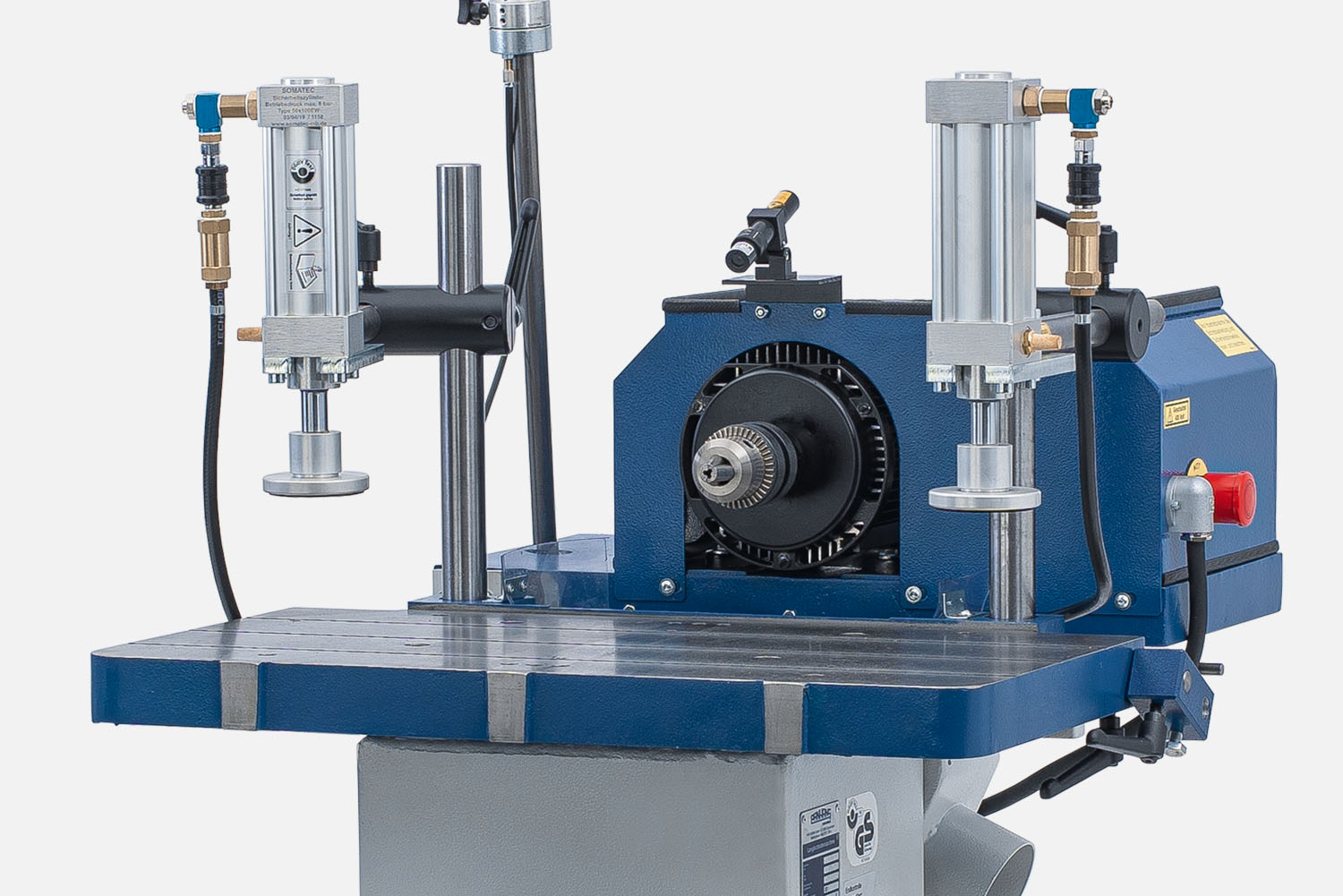

Slot drilling & mortising machine

116|10

Motor Power

1.3 kW / 1.8 HP

1.7 kW / 2.3 HP

VOLTAGE

400 V / 50 Hz

H x W x D in mm

1250 x 1010 x 1280

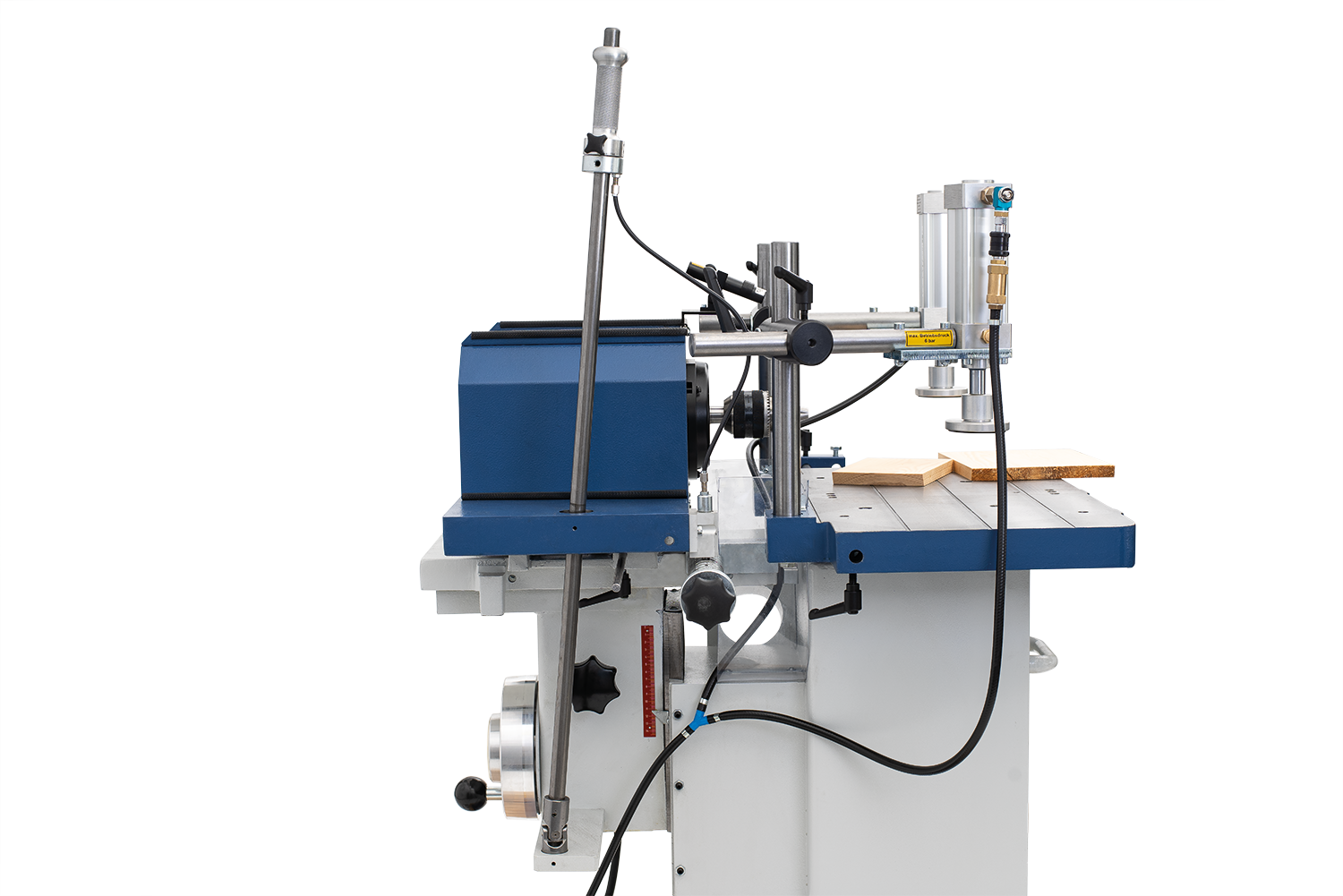

With our solid and high quality processed slot drilling and mortising machine 116|10 you get a professional woodworking machine designed and manufactured in Germany in the well-known PANHANS quality.

Features such as drilling length and drilling depth limiters, stop rod for series processing, frame and mitre fence, dowel indexing device, a mobile base, a finely planed table top made of solid cast iron as well as two eccentric clamps are already part of the standard equipment.

Die beiden fixen Spindeldrehzahlen von 1500 und 3000 U/min sind durch Umlegen eines Wahlhebels umschaltbar. Longitudinal and transverse adjustment of the drilling unit is via two-lever operation.

The cross support runs easily in adjustable ball guides, and the transverse movement resp. desired length of the mortise can be limited by lateral stops.

A possibly required drilling depth can be set by a stop with scale. The height of the drill support can be precisely adjusted by means of a handwheel with scale. This slides in an adjustable dovetail guide and can be locked by means of a cross handle.

An infinitely variable drilling speed via frequency inverter as well as a one-hand operating lever and numerous other useful features are optionally available.

ART. NO. 4237

EXCENTRIC CLAMPS

Two robust hand lever eccentric clamps are infinitely adjustable in height.

HANDWHEEL

Handwheel with indicator for height adjustment of the drilling unit.

TOOL TRAY

The practical tool tray above the drilling unit supports clean and tidy working.

MOBILE BASE

Thanks to the mobile base, the location of the slot drilling and mortising machine can be changed. The mobile base is mounted in the machine stand and equipped with a sturdy push bar at the front.

HAND LEVER CONTROL

Two-hand lever control for longitudinal and transverse movement of the drilling unit.

Technical specifications

EQUIPMENT DETAILS

EQUIPMENT DETAILS

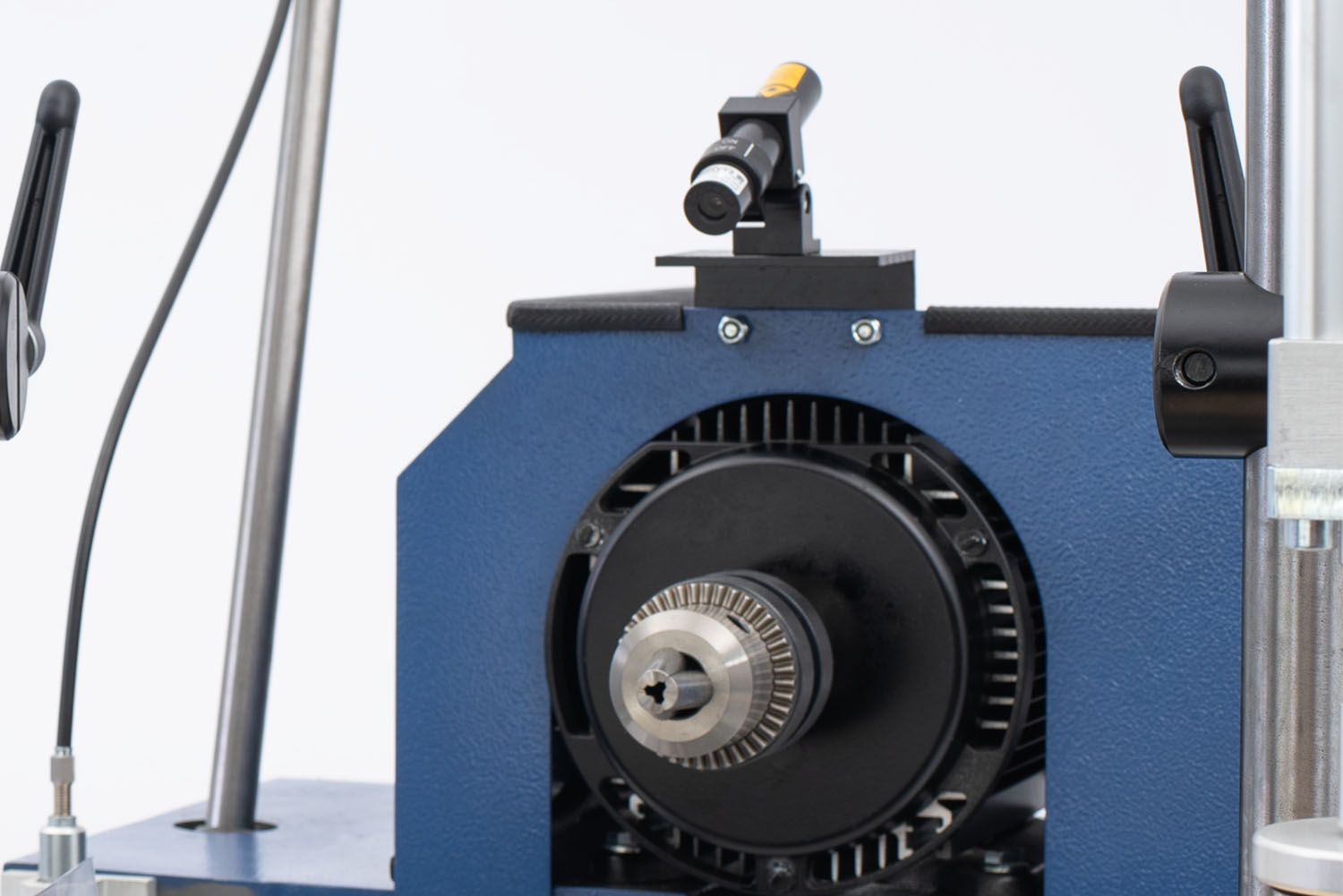

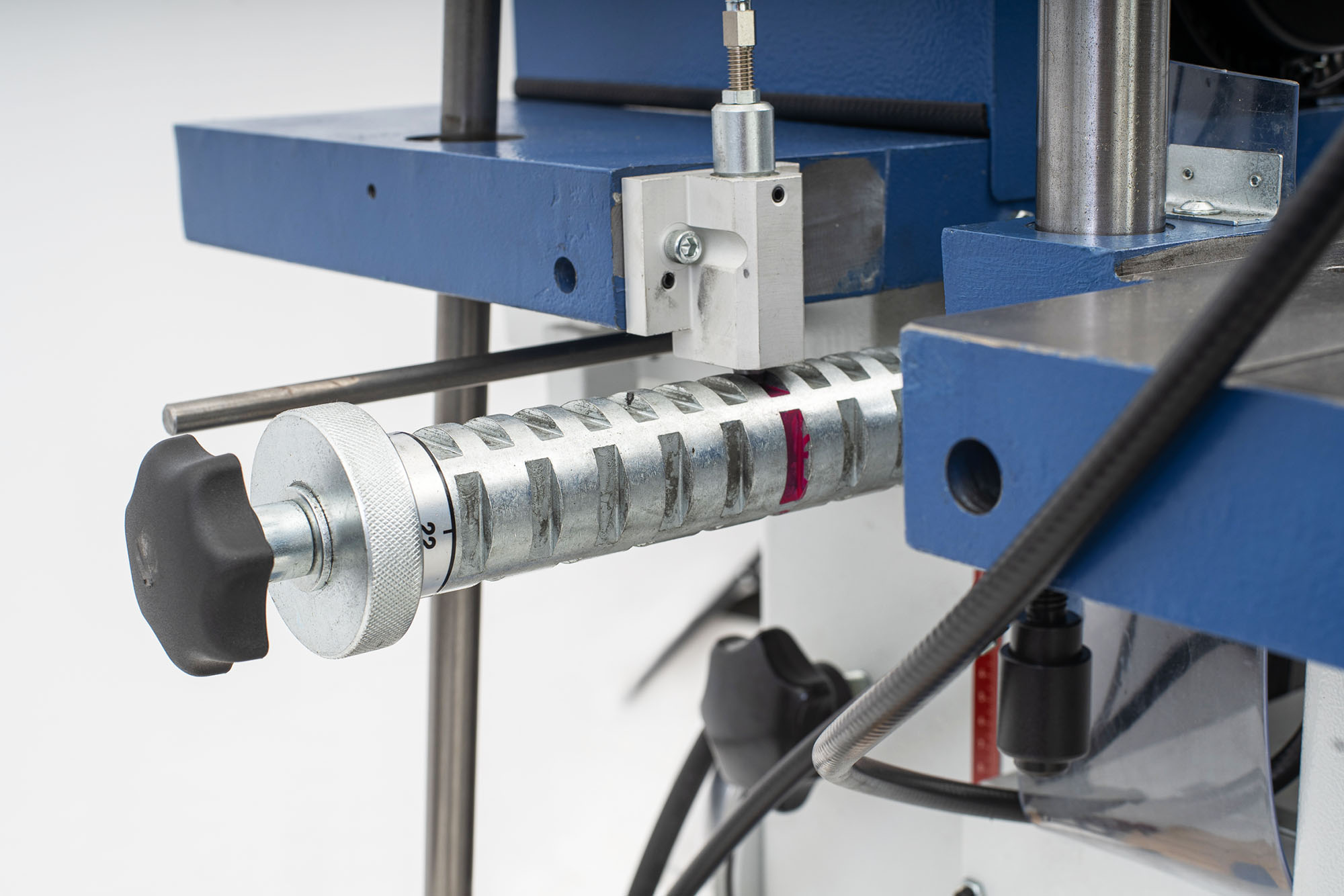

DOWEL INDEXING DEVICE

Dowel indexing device for hole line drilling with precision indexing barrel 16, 22, 25 and 32 mm, high-precision milled grid and fixing via spring-loaded index bolt.

EQUIPMENT DETAILS

Frame stop

Plug-in frame stop with index bolts for the positions: centre, left, right.

EQUIPMENT DETAILS

Mitre fence

Mitre fence pluggable with index pins for fixed degrees 45° and 22.5°.

EQUIPMENT DETAILS

Workpiece attack

A laterally extendable workpiece length stop with infinitely variable adjustment up to 1500 mm for series processing is standard on all PANHANS slot drilling and mortising machines.

OPTIONS

Option

SINGLE LEVER CONTROL

Instead of two-hand lever control for longitudinal and transverse movement (X and Y axis) of the drilling unit. Including remote locking for loosening and fixing on the indexing barrel. Narrow workpieces can thus also be drilled from the front. The change from drill hole to drill hole during dowel hole drilling is considerably accelerated and simplified.

Option

DIAL GAUGE

Accurate and precise drill height adjustment in the Z-axis by the analogue dial gauge in the handwheel with 0.1 mm graduation.

Option

TWO PNEUMATIC SAFETY CLAMPING CYLINDERS

The workpieces are clamped safely and user-friendly by pneumatic safety cylinders. The effective stroke of 100 mm allows a wide range of adjustment of different workpiece thicknesses without having to make an extra adjustment. The cylinder is a sophisticated clamping system that generates a high clamping force and at the same time prevents injuries to the hand.

Option

DOUBLE-SIDED MITRE FENCE

Adjustment fence for mounting on the machine table. With analogue scale and for infinitely variable mitre settings from 22.5° to 75°.

Option

BATTERY OPERATED LASER

For drill line marking when drilling on scribe marks. The laser beam is red with a line length of approx. 300 mm.

Option

MAINS-POWERED LASER

Power connection with 230 V and safety plug. For drill line marking when drilling on scribe marks. The laser beam is red with a line length of approx. 300 mm.

Option

VARIABLE DRILLING SPEED CONTROL

Variable speed control of the drill spindle via frequency inverter. The speed of the drill spindle can be infinitely adjusted via an adjusting wheel.

Option

LOCKABLE EMERGENCY STOP BUTTON

The emergency stop button can be locked with a key.

Option

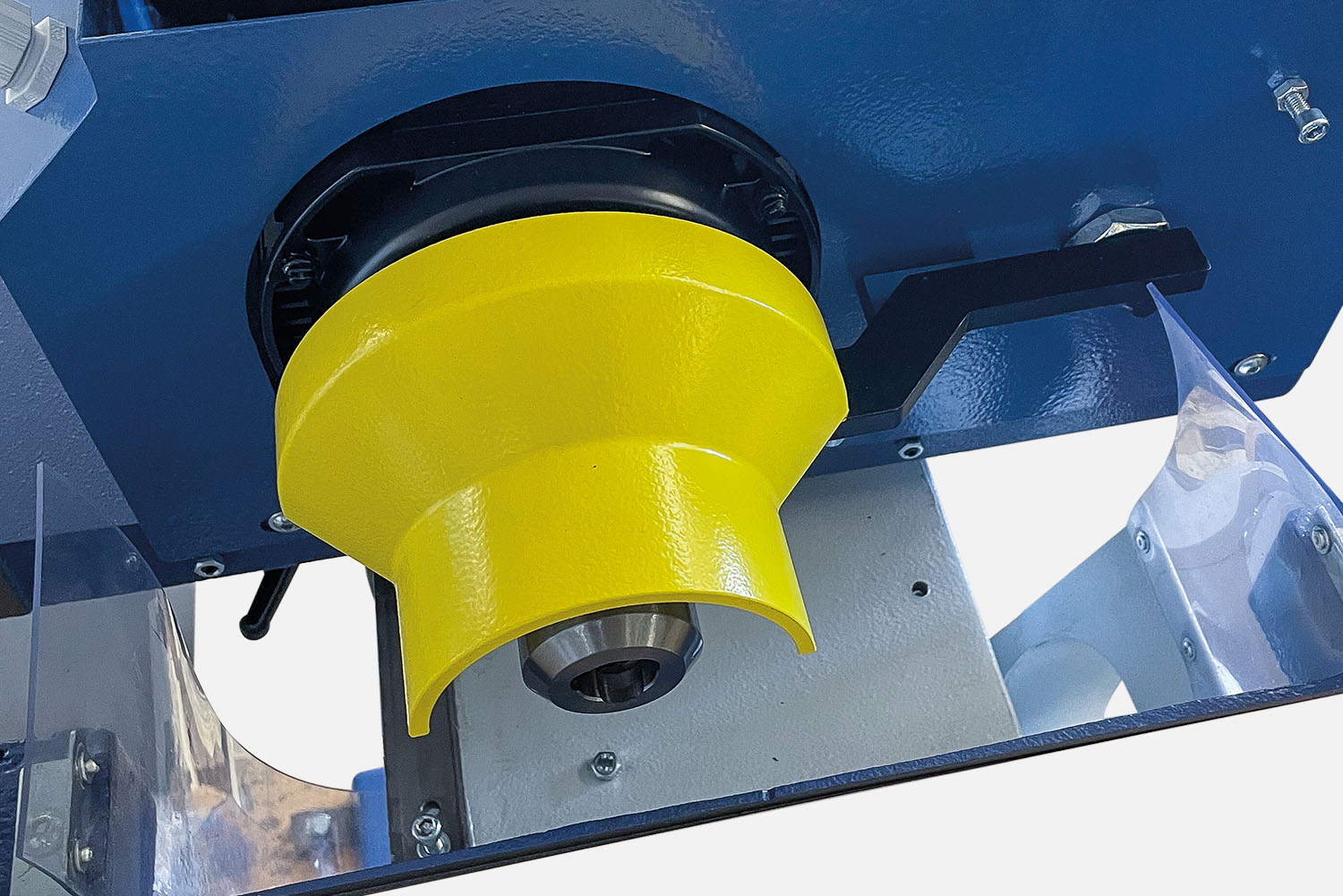

SAFETY PROTECTION COVER

Safety protection cover with electrical interlock above the drill chuck. The guard prevents the drill spindle from starting unintentionally. The motor only starts when the guard is folded down. Recommended in training centres for more safety.

Option

COLLET CHUCK

The collet chuck ensures even greater precision in concentricity with clamped drilling bits. The collet has a collet chuck with a Ø 10 mm collet instead of the standard three-jaw chuck.

Option

EXTRA COLLET

Extra collet for collet chuck diameters 2 - 20 mm depending on customer's request.