Thickness planer

436|100

Motor Power

7.5 kW / 10 HP

VOLTAGE

400 V / 50 Hz

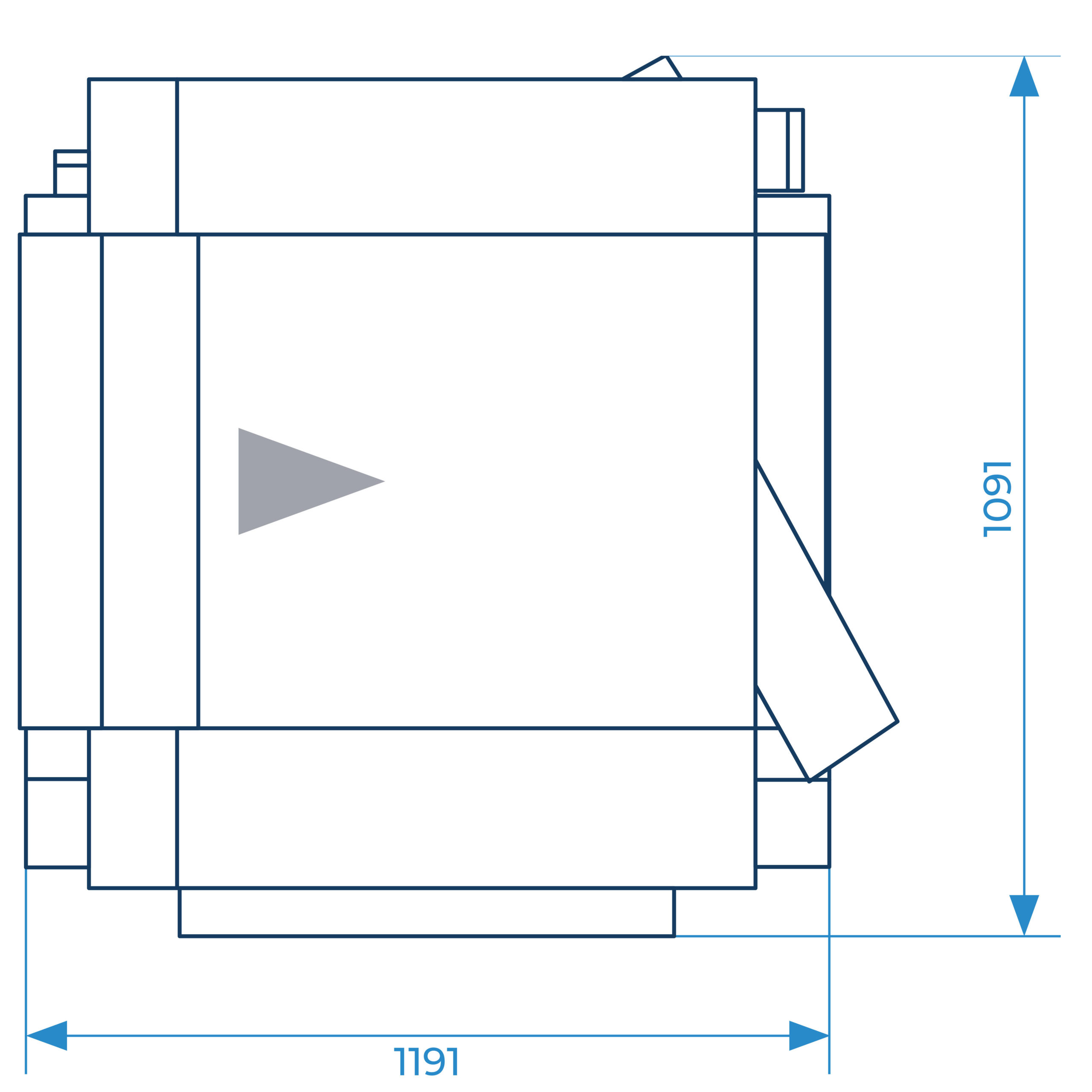

H x W x D in mm

1114 x 1091 x 1191

With its precise, reliable and long-lasting use, a planing width of 630 mm and an impressive chip removal of 8 mm, the massive yet compact PANHANS thickness planer has already convinced numerous carpenters, joiners and woodworkers around the world. This is also made possible by the maintenance-free bearing construction with high-performance precision ball bearings.

The robust steel construction and the dynamically balanced TERSA cutter block, together with the powerful 7.5 kW motor, ensure extremely smooth and quiet running even under heavy loads.

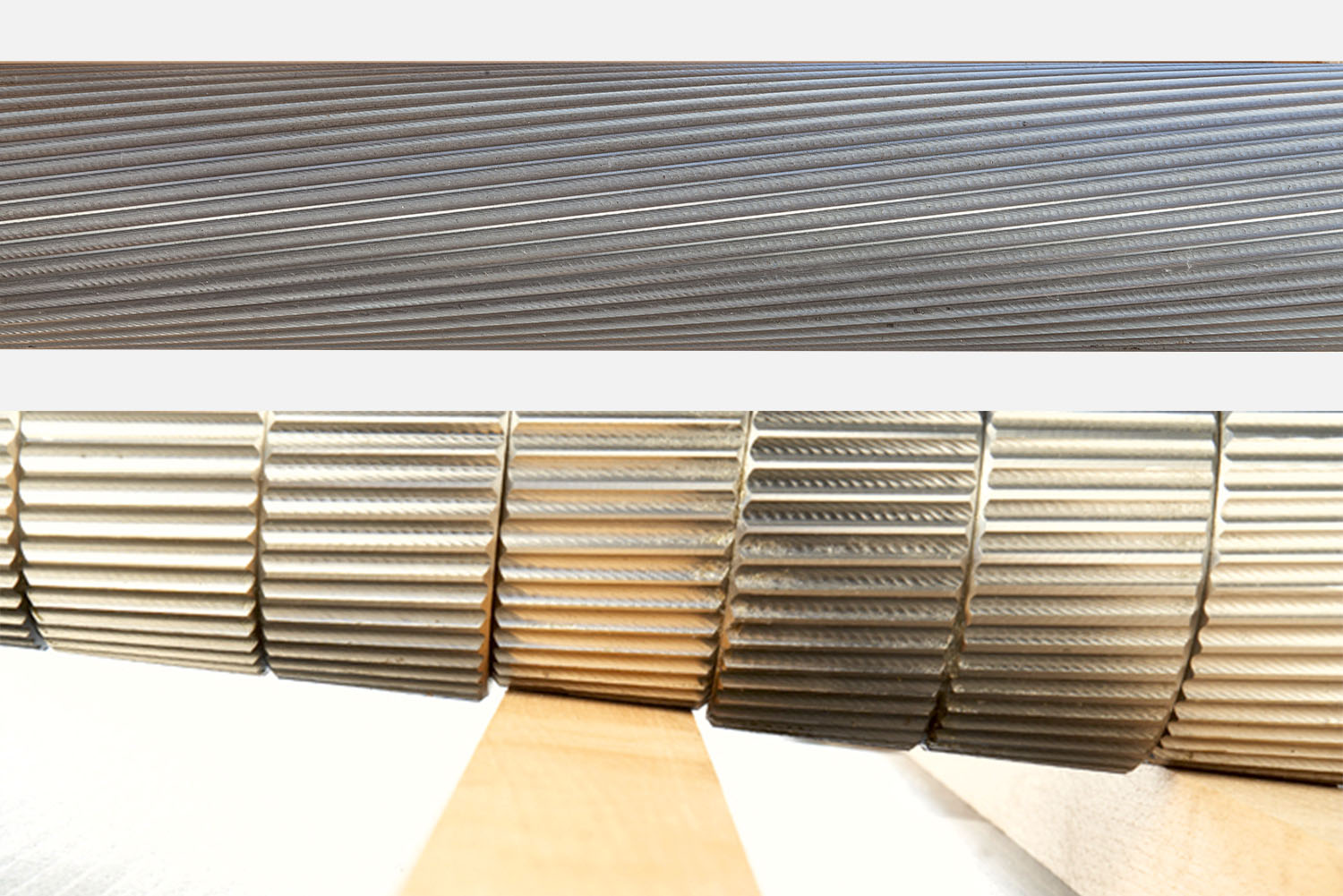

Optionally, the machine can be equipped with a spiral cutter block with 4-fold carbide inserts. The "pulling cut" enables longer service lives and even smoother running.

Pendulum-mounted infeed and outfeed rollers as well as segmented pressure beams guarantee jerk-free transport of the workpieces to be machined. The 1620 mm long thicknessing table has a finely planed surface made of solid grey cast iron and its air cushion effect prevents the workpieces from sticking on the table top.

The infeed side contains a control panel with all the important functional elements for starting/stopping the cutter block and feed unit as well as for releasing the motor brake. Above the control panel is the newly developed touchscreen control for setting the height of the thicknessing table, indicating the feed rate and status messages, and setting operating parameters.

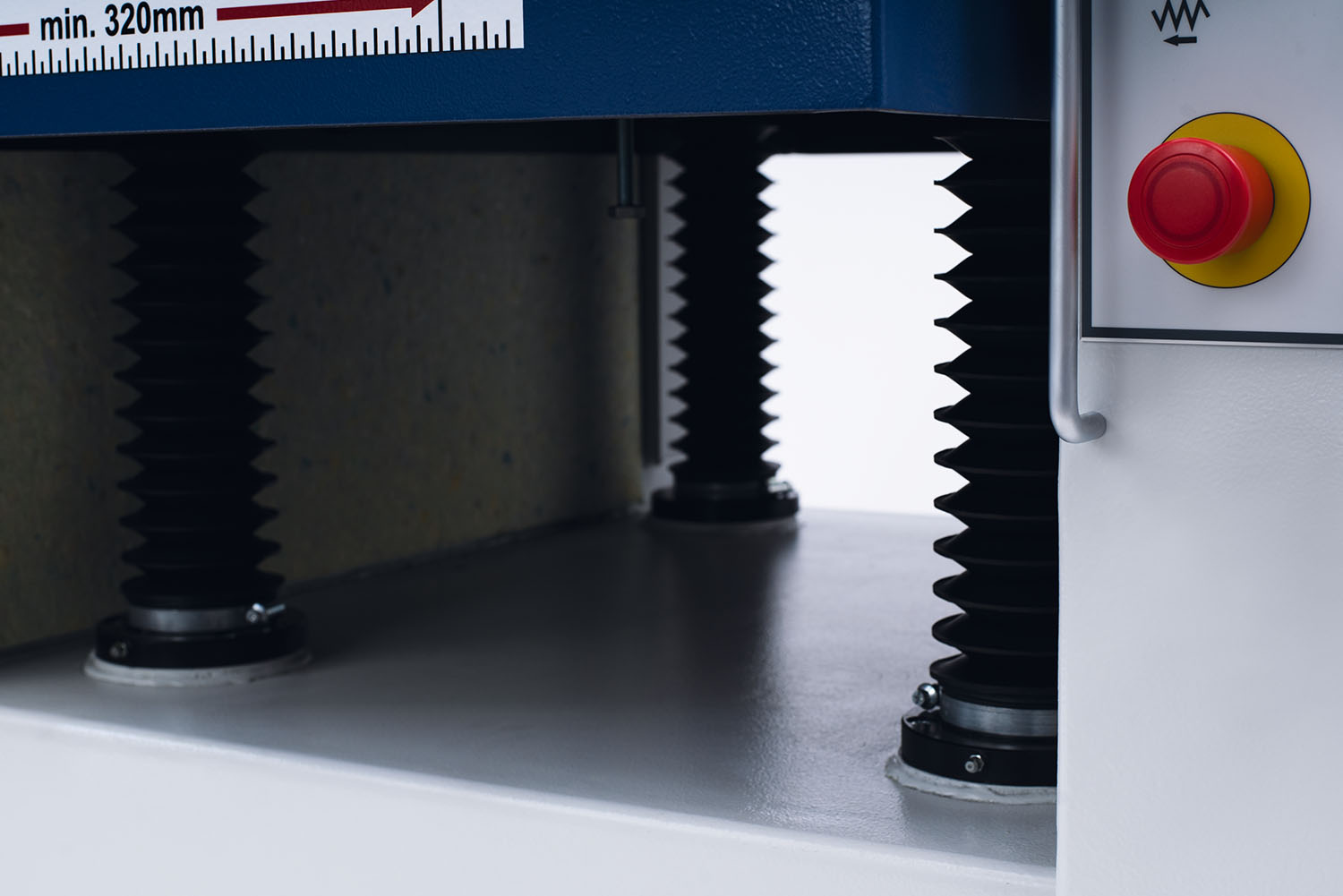

The machine is equipped as standard with an effective anti-kickback device and all the necessary safety devices.

Optionally, the proven PANHANS thicknesser can be extended with various table extensions and other specific components.

ART. NO. 4373

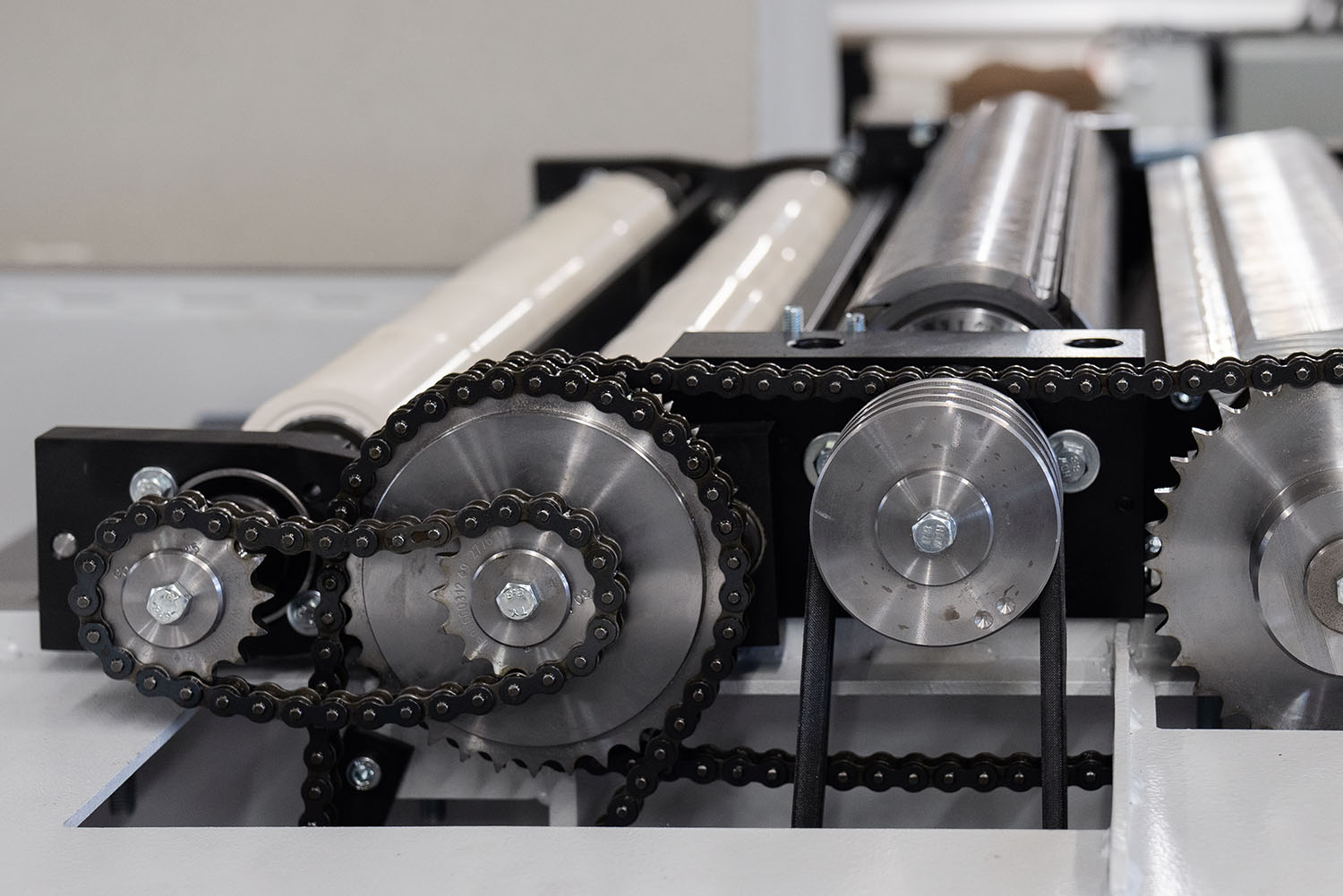

INFEED & OUTFEED ROLLER

Jolt-free throughfeed of the timber is ensured by pendulum-mounted infeed and outfeed rollers and segmented pressure beams. This results in smooth transitions when planing and no impact effect is exerted on the workpiece.

NEW CONTROL SYSTEM

All relevant values are set via a touchscreen control. This is robust and easily accessible for simple operation and

control.

PUSH-SWITCH UNIT

The push-button circuit controls the start and stop process as well as the mechanical motor brake.

TRAPEZOIDAL SPINDLES

The thicknessing table rests on four solid trapezoidal threaded spindles for precise guidance and high loads.

MAIN MOTOR

The powerful 7.5 kW main motor also guarantees chip removal from 8 mm to 630 mm without compromise.

STORAGE AREA

The soundproofed machine bonnet serves as a practical storage surface. Workpieces can be placed on it between processing steps.

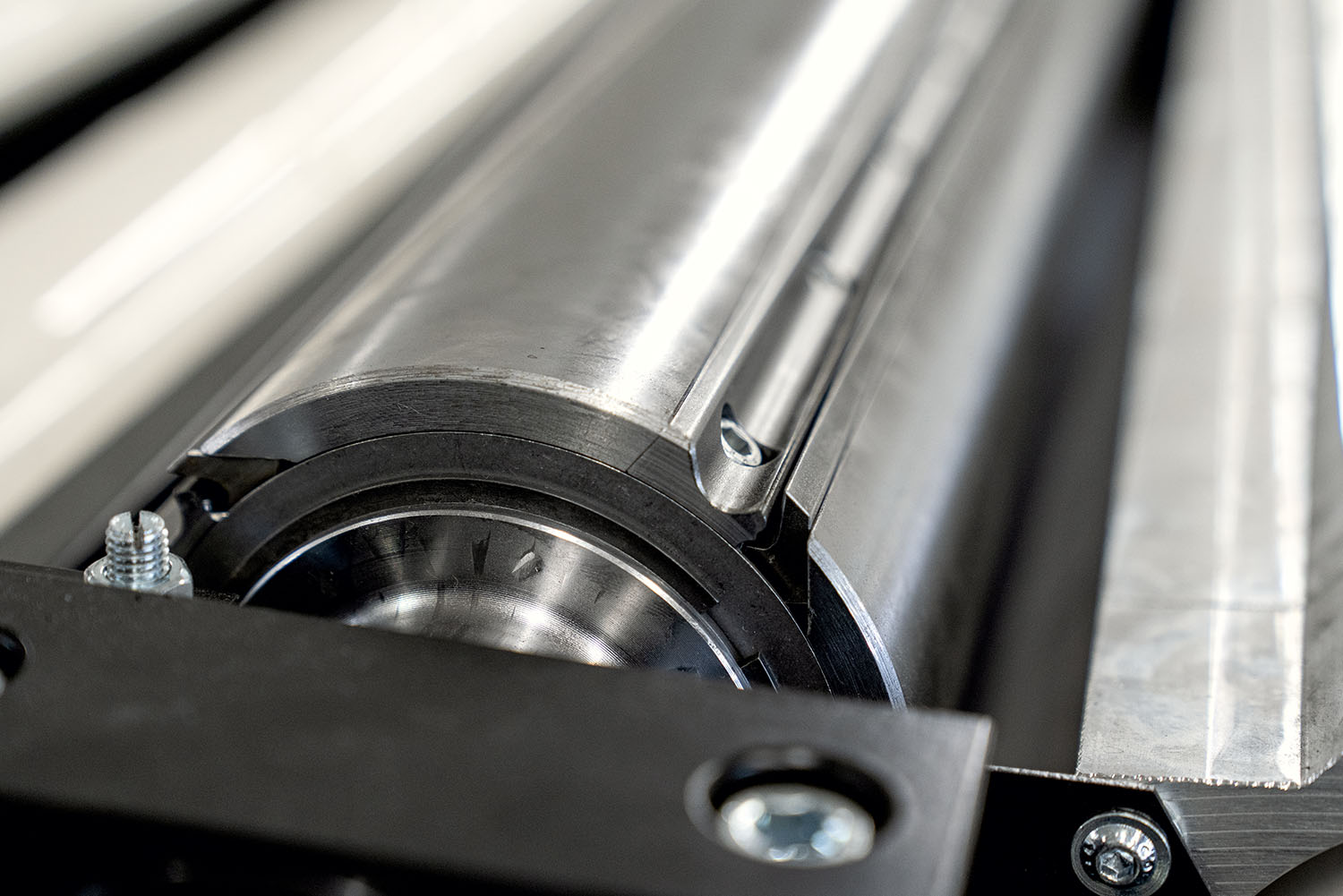

THICKNESSING TABLE

The table top is finely planed to create an air cushion effect between the workpiece and the table surface. This facilitates workpiece handling.

OPTION: TABLE EXTENSION

Mounted on the machine table in the outfeed area with automatic height adjustment for particularly long workpieces.

Technical specifications

EQUIPMENT DETAILS

EQUIPMENT DETAILS

TOUCHSCREEN CONTROL PANEL

The touchscreen enables convenient operation. Positioning sequences and command inputs can be controlled directly by touching the smooth monitor surface. As there are no individual buttons and therefore no gaps, the control unit is largely insensitive to dust, dirt and moisture. Particular emphasis is placed on intuitive operation.

EQUIPMENT DETAILS

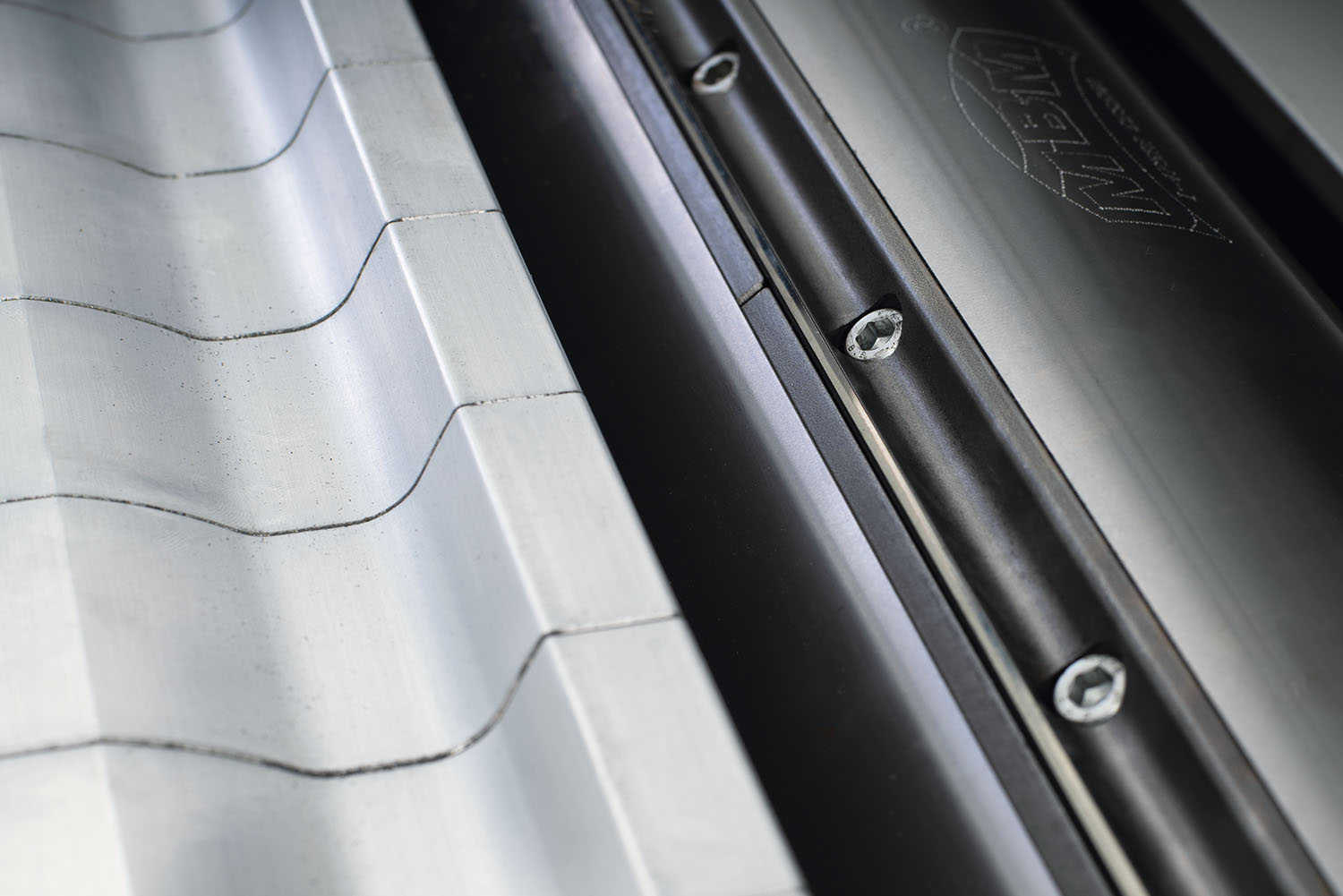

SEGMENTED PRESSURE BEAMS

The segmented pressure beams enable optimum contact pressure on the planing table. This is particularly important when planing workpieces of different heights at the same time.

EQUIPMENT DETAILS

THICKNESSING TABLE WITH 4 TRAPEZOIDAL SPINDLES

The thicknessing table is mounted on four solid trapezoidal threaded spindles with two additional lateral guides to prevent tilting. It is guided in parallel and designed for high loads. The absolute precision achieves an optimum planing result.

EQUIPMENT DETAILS

TERSA CUTTER BLOCK

With four reversible knives for quiet operation and quick knife changes as well as precise automatic knife adjustment.

OPTIONS

Option

TABLE SLIDE ROLLER

Optional equipment on the 436|100 includes two table slide rollers with steel infeed and rubber outfeed roller as well as fine adjustment on the thicknessing table via handwheel. Ideal for processing moist and resinous woods. Recommended for construction companies, carpentries and sawmills.

Option

THICKNESSING TABLE EXTENSION

Thicknessing table extension 630 mm wide with automatic height adjustment to prevent the workpieces from tipping; can be mounted at the infeed and outfeed side.

Option

SECOND OUTFEED ROLLER

The two segmented rubber outfeed rollers are used for better outfeed to prevent premature tilting of the workpiece and ensure smooth and safe workpiece outfeed. An additional advantage: The second pull-out roller prevents planing impacts.

Option

STEEL INFEED ROLLER & SEGMENTED STEEL OUTFEED ROLLER

Steel feed roller instead of standard rubber feed roller, recommended for damp or rough sawn timber. Segmented infeed roller for thickness compensation of approx. 3 mm when planing several battens next to each other.