Tilting spindle moulder

245|10

Motor Power

5.5 kW / 7.5 HP

VOLTAGE

400 V / 50 Hz

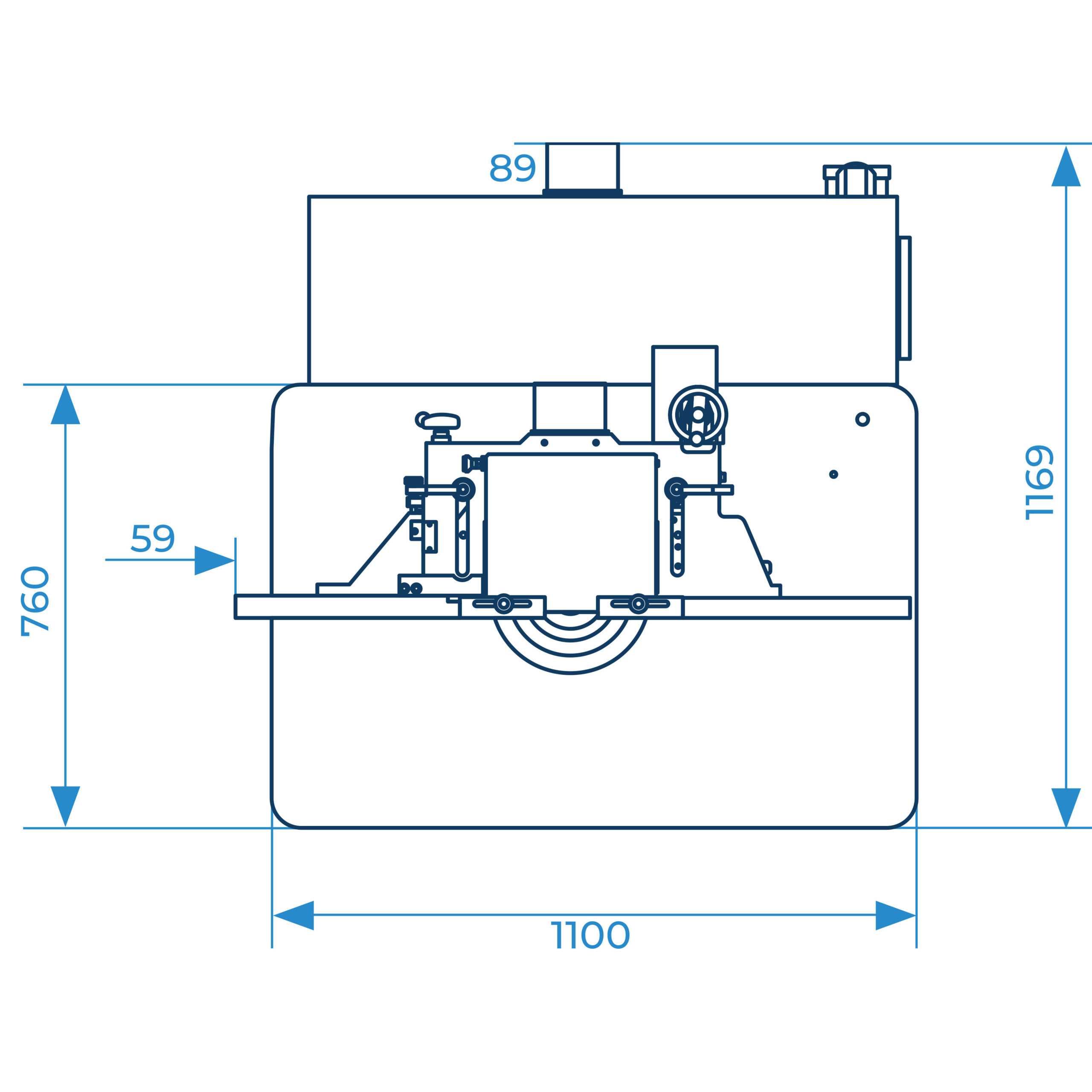

W x D in mm

1100 x 1169

The PANHANS 245|10 model is a compact universal tilting spindle moulder and shaper with height and tilt adjustable milling arbor, two directions of rotation, quick tool change device, adjustable speed and separately adjustable total and partial fence.

The exclusive use of high-quality parts and components guarantees the highest precision, absolute reliability and a long service life when machining wood or plastics.

At the same time, this wood milling machine has been deliberately designed without electronic controls and functional elements, and the design has been kept as compact as possible so that it can also find its place in smaller joineries, carpentry shops and workshops.

The milling spindle is driven by a three-phase motor, and the machine's four speeds (3000, 4500, 6000 and 9000 rpm) can be adjusted by shifting the belt pulley via a quick-action clamping device.

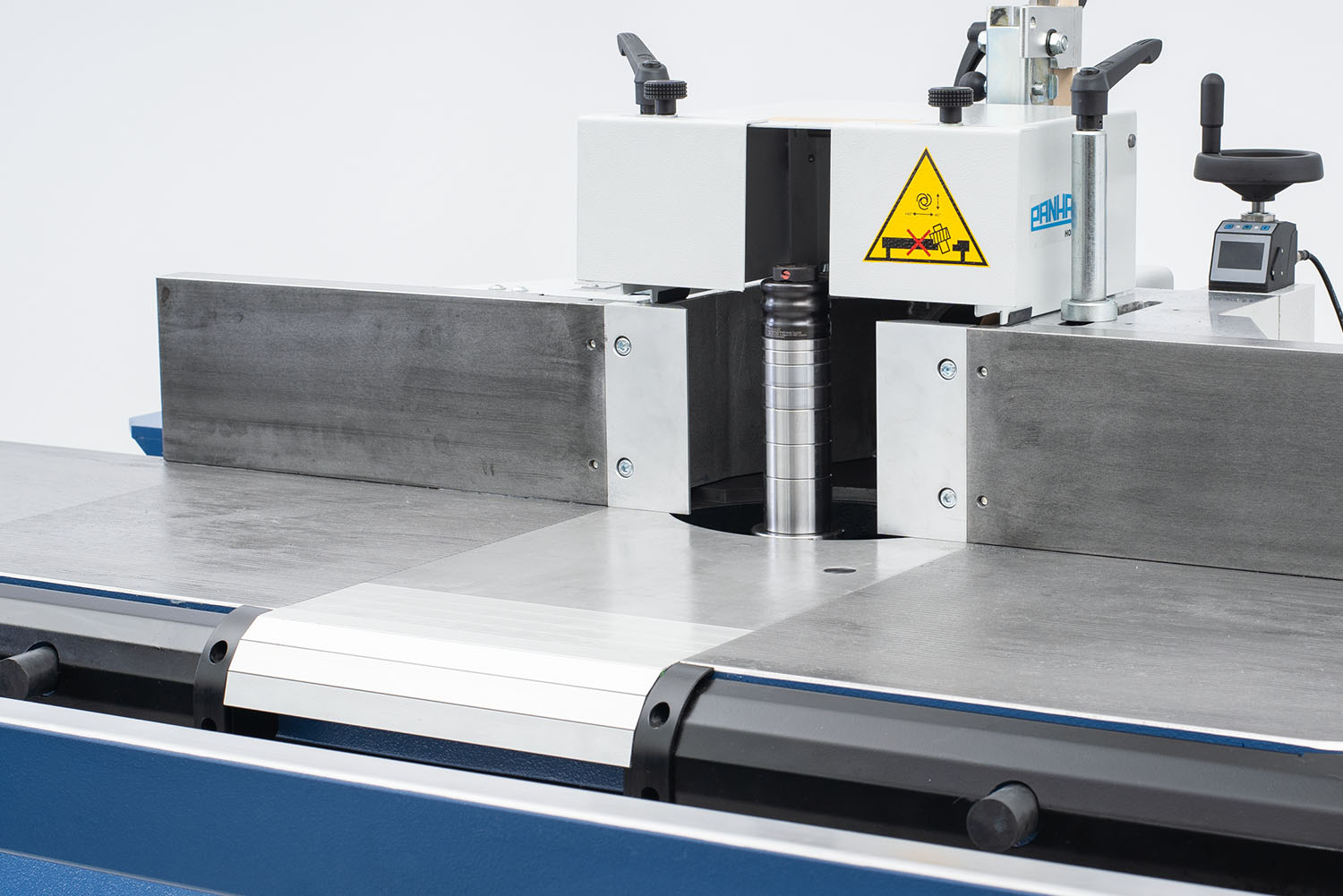

The 30 mm milling spindle, which is tiltable in the range from -5° to +45.5° and designed for clockwise and anticlockwise rotation, is mounted in dust-tight bearings. Special ball bearings and careful alignment of all moving parts give the machine smooth and quiet running.

Height and tilt adjustment is manual via two front-mounted handwheels with analogue indicators.

The standard safety fence type 215 can be adjusted manually in part and in full and is equipped with a protection cover and the Protection and pressure device type 1629 GAMMA V.

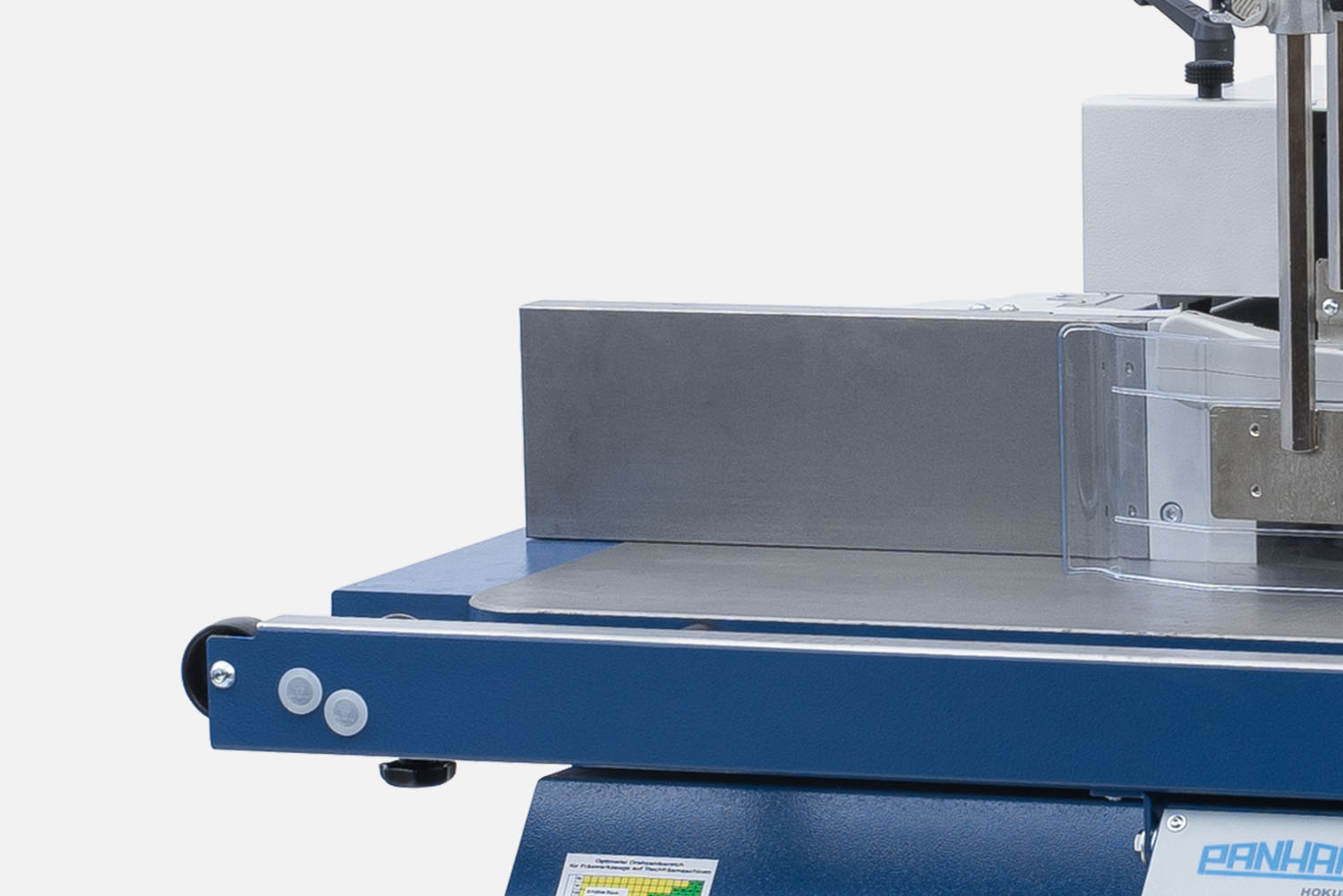

The finely planed cast iron machine table has the dimensions 1100 x 760 mm and has a rigid frame support. It can be optionally extended with an extendable frame support and upgraded with a turntable.

Thanks to the integrated machine socket, the machine is already prepared for the connection of a power feeder.

Like all PANHANS machines, this model also has all the required safety devices and is already extensively equipped in the basic version.

ART. NO. 4523

MILLING SPINDLE

Spindle moulder with fixed milling spindle tiltable on one side for a tilt range of -5° to +45.5°.

MILLING FENCE

The standard milling fence 215 has multiplex plates. Overall adjustment via handwheel and individual jaw adjustment via star grip and scale.

CAST IRON TABLE

Finely planed grey cast iron table for optimum processing and durability.

MAIN SWITCH

The lockable main switch ensures greater safety when working. The machine is also equipped with an electric motor brake and a machine socket.

CONTROL UNIT

Operation via handwheels, easily accessible at the bottom of the machine body.

MOTOR POWER

With a motor output of 5.5 kW, 4 speeds are available in the standard version, which can be adjusted by changing the position of the drive belt.

DIAL GAUGES

The height and tilt adjustment is indicated by the analogue dial gauges in the handwheels.

TECHNICAL SPECIFICATIONS

EQUIPMENT DETAILS

Equipment

OPERATION VIA HANDWHEELS

The analogue dial gauges indicate the current positions. The height and tilt adjustments are made manually

manually using handwheels.

EQUIPMENT DETAILS

4 DIFFERENT SPEEDS

The four speeds 3000 / 4500 / 6000 / 9000 rpm are indicated digitally by corresponding signal lamps and adjusted by a quick belt tensioning device.

OPTIONS

Option

MILLING FENCE TYPE 216

The total adjustment can be made using the handwheel and the LCD display. The individual jaws, including the

cast stop plates, are adjusted using a star grip and scale.

Option

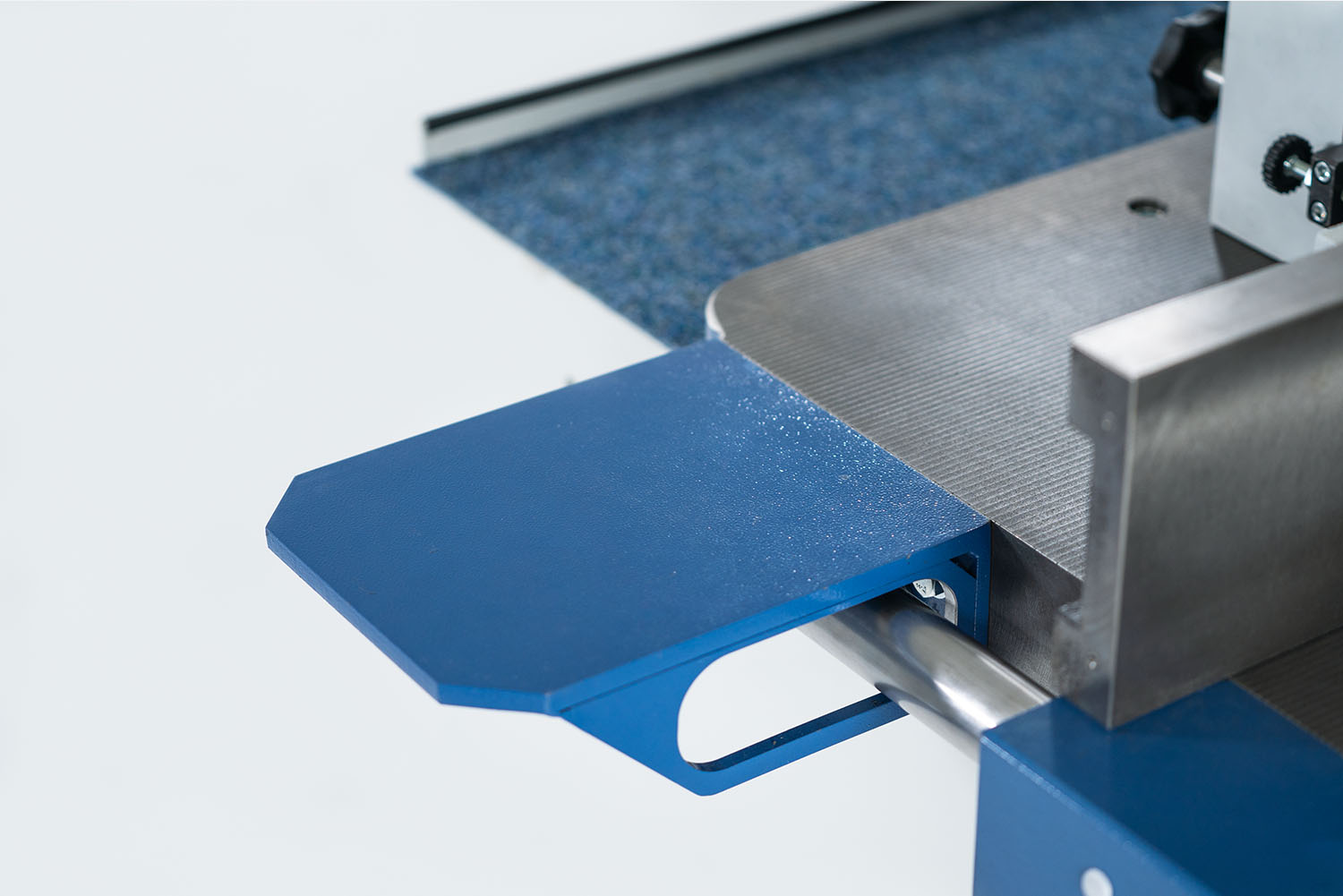

RIGID CONSOLE

For mounting a power feeder approx. 195 x 180 mm on the left side of the table top; mandatory when using milling fences 204, 302, 320 and integral fence plates 650 + 650 mm, with table top 1100 x 760 mm.

Option

HYDRAULIC SWIVEL-AWAY DEVICE

The hydraulic swivel-away device ensures convenient and safe lifting and swivelling away of the milling fence. This can be lifted off the table and swivelled backwards quickly and effortlessly during curved or arch milling work.

Option

TURNTABLE

This allows the milling fence on the machine table to be rotated by 360° (only for table top 1100 x 760 mm).

Option

EXTENDABLE FRAME SUPPORT, FOR TABLE TOP 1100 X 760 MM

Total length approx. 1375 mm, extension depth approx. 892 mm from the centre of the milling spindle, guided in separate bearing blocks on the side of the machine table, smooth-running and with emergency stop button.

Option

TABLE TOP EXTENSION ON BOTH SIDES

For table top 1100 x 760 mm, total length 2300 mm, consisting of 2 finely planed cast table tops as extensions on the left and right of the standard machine table, with smooth-running frame support, can be extended forwards by approx. 870 mm, incl. emergency stop button.

Option

KICK-BACK GUARD TYPE 1648

For accident-safe insert milling of long and short parts, infinitely adjustable from 0 - 1500 mm, for milling machines with table top extension.

Option

SLIDE PLATE FOR TABLE TOP 1100 X 760 MM

The patented slide plate with grid structure does not change the overall depth when the table slide is set to the maximum table openings. For easy operation, the distance between the front edge and the spindle remains the same. The table slide is infinitely adjustable in depth. A high fitting accuracy without interfering edges is guaranteed.

Option

SAFETY GUIDE BAR SET FOR MILLING FENCES

As a continuous guide between the two fence plates, consisting of 2 safety guide bars 260 x 6 mm, 3 safety guide bars 260 x 3 mm, 1 grooved board made of multiplex 260 x 150 x 12 mm, incl. sliding blocks and Allen key.

Option

CENTREX

Protective and pressure device for securely fixing the workpieces during manual milling work; the

special shape of the pressure shoe ensures precise workpiece guidance during all milling work,

attached to the milling fence, can be folded up, instead of standard GAMMA protective and pressure device

V 1629.

Option

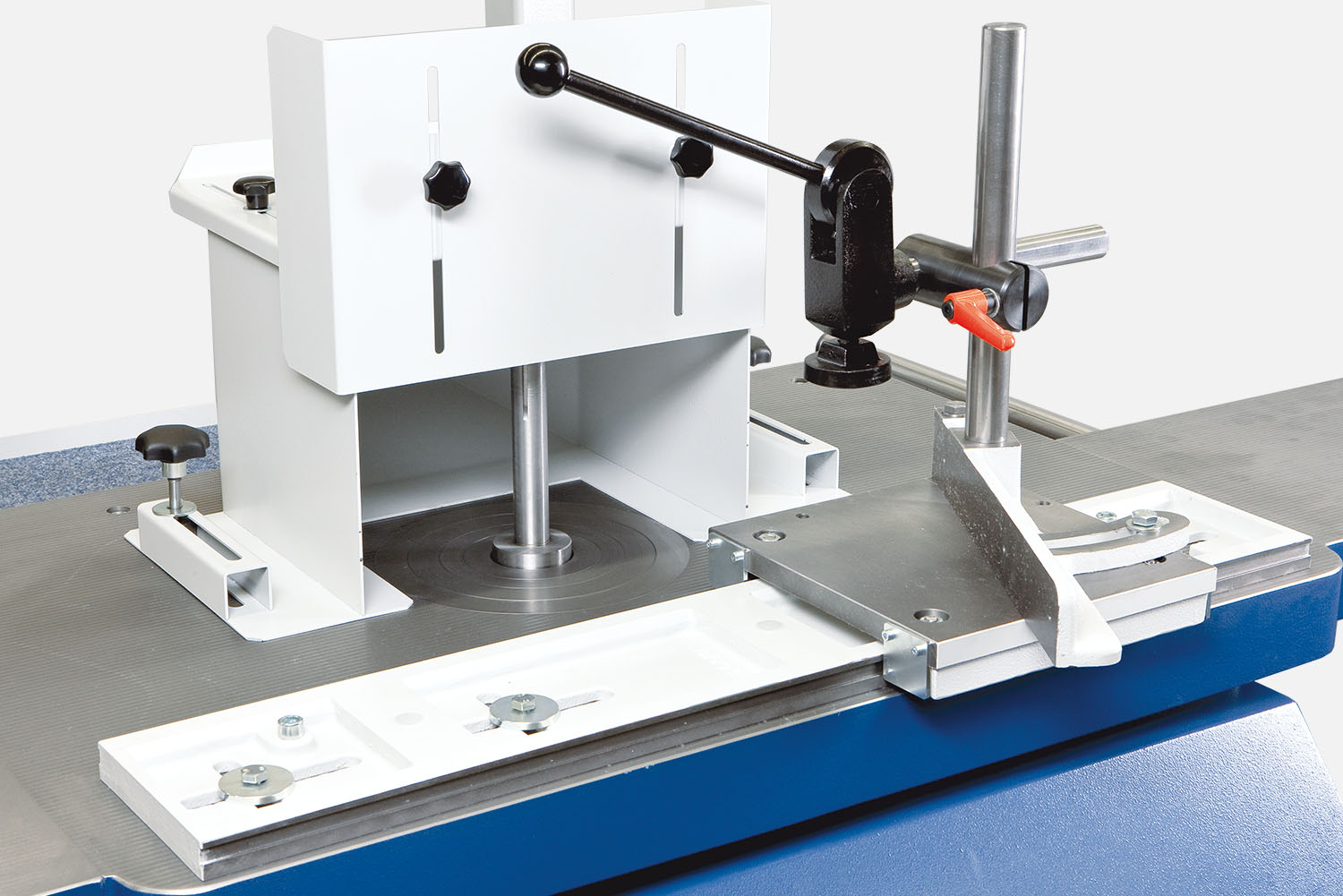

TENONING AND SLOTTING DEVICE 1376

Mounted on the machine table for light tenoning and slotting work; with eccentric clamp and

mitre-adjustable stop. Sliding stroke 710 mm, height above table approx. 56 mm. The safety guard type 1641 must be used when working with the 1376 tenoning and slotting device.

Option

SAFETY GUARD 1641

for the tenoning and slotting device, incl. suction nozzle with 120 mm diameter, suitable for tool diameters fom 250 mm

to 350 mm.

Option

POWER FEEDER PV 84

4 rollers 120 x 60 mm, 8 speeds: 2/4/5.6/6.7/11/13/16.5/33 m/min, clockwise and anti-clockwise rotation, stand with extension arm 1050 mm, can be used individually horizontally and vertically, incl. mounting, cable and plug.

Option

POWER FEEDER VARIOMATIC 4 N

With 4 rollers, infinitely variable feed rate from 2 - 18 m/min. Clockwise and anti-clockwise rotation,

quick rotation from horizontal to vertical use; easy swivelling and positioning with memory lock system; with comfort stand, numerical height display, boom arm 1050 mm long, incl. mounting, cable and plug.