Tilting spindle moulder

245|300

Motor Power

7.5 kW / 10 HP

VOLTAGE

400 V / 50 Hz

W x D in mm

1375 x 1480

The PANHANS tilting spindle moulder type 245|300 is the masterpiece of the 245 series. With it, not only the spindle height and the angle of inclination, but also the solid total and partial fence type 320 can be positioned fully automatically. In this way, furniture and components as well as window and door elements can be produced quickly, efficiently and accurately without much set-up effort.

The central element of the machine is the intelligent four-axis touchscreen control, which positions all axes (height and tilt of the spindle as well as the total and partial fence) by means of an electric motor based on corresponding target value entries. At the same time the control unit permanently monitors the status of the machine according to aspects relevant to operation and safety. The machine can only be started if all conditions required for operation are met. Otherwise, a corresponding message is indicated for troubleshooting.

All target and actual values as well as the tool and program data required for the work are clearly visualised on the screen interface and can be viewed and edited at a glance.

Also integrated into the operating concept is the extensive tool database. Up to 500 tools and up to 100 programs per tool can be stored in this database. Various cutters and components such as trims for doors and windows can be conveniently stored and are available when needed.

Another special feature of this model is the continuously adjustable speed in the range 1500 to 10000 rpm for the ±45° tiltable milling spindle. The speed is also set and indicated via the touchscreen control.

The powerful 7.5 kW three-phase motor provides the necessary performance to always achieve reliable and precise machining results, even under heavy load. A wear-free electronic motor brake ensures a fast and safe standstill when the spindle is switched off.

Like all PANHANS machines, the model consists exclusively of high-quality components and is fully equipped with all the necessary guards and safety devices as standard. If required, the range of functions can be expanded with extensively available options and accessory components and the machine can thus be individually adapted to the respective customer requirements.

ART. NO. 4622

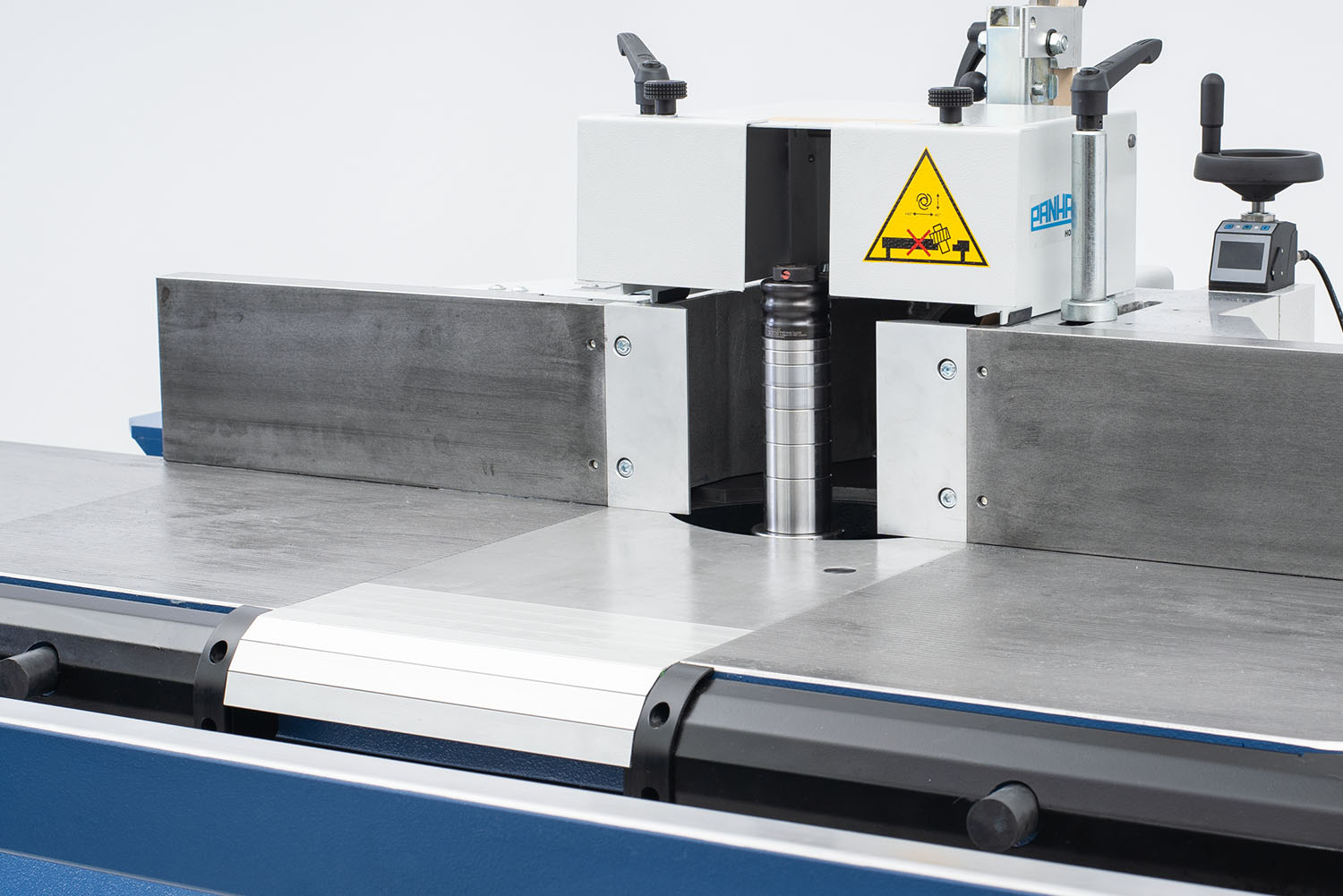

MILLING SPINDLE

Fixed and double-sided tiltable by +/- 45.5° with quick-release device.

CAST IRON TABLE

Finely planed and with rigid frame support.

7" TOUCHSCREEN CONTROL

Capacitive touchscreen (scratch and impact resistant), can also be operated with gloves. The touchscreen control can also be mounted on the fixed (or optionally extendable) frame support. For height and tilt adjustment, speed visualisation and positioning the total and partial fence.

SPEED CONTROL

Electronic, infinitely variable speed control from 1,500 - 10,000 rpm (11 kW frequency converter).

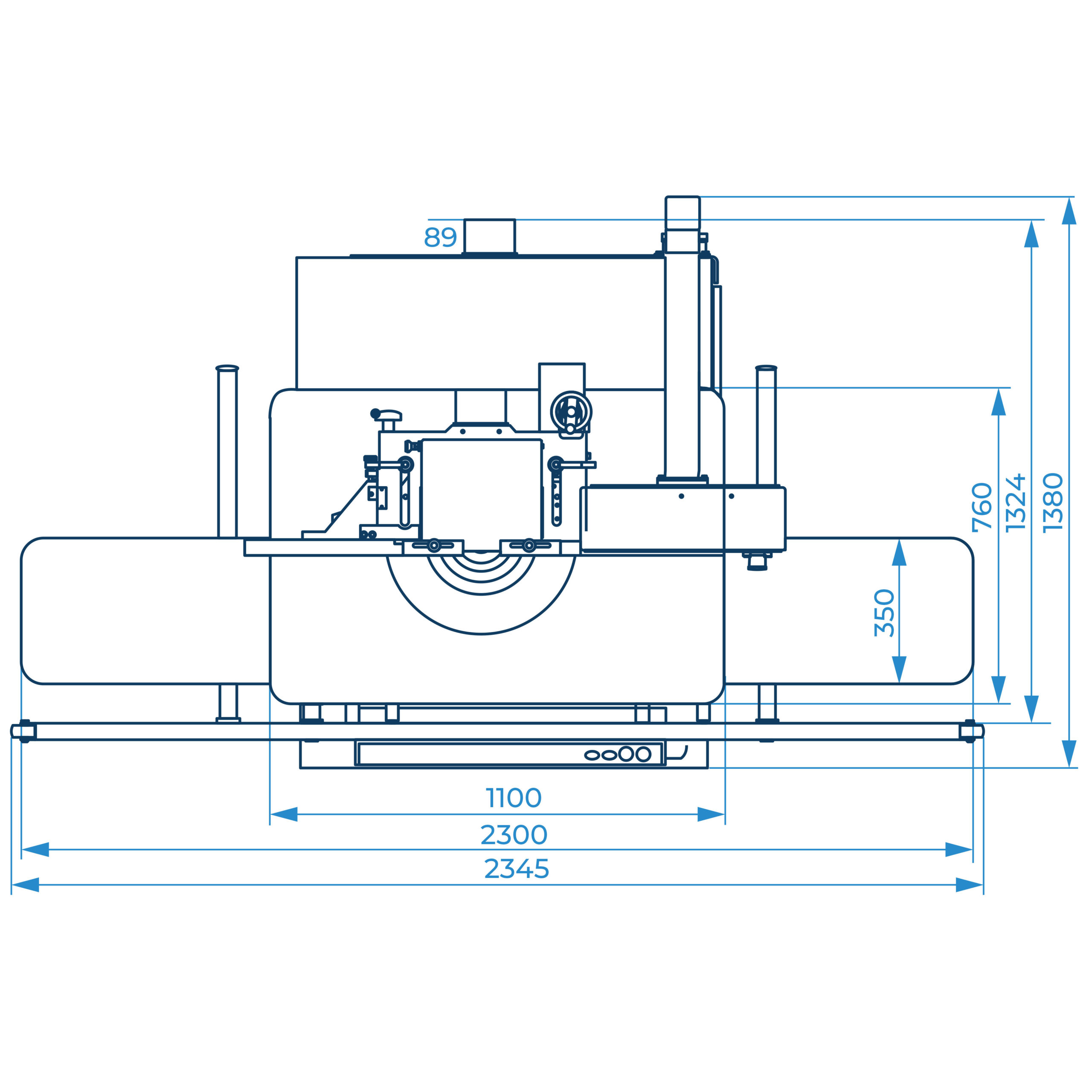

OPTION: TABLE EXTENSION ON BOTH SIDES

The table extension is double-sided and has a total length of 2300 mm, with an extendable frame support at the front.

OPTION: COMFORT SWIVEL-AWAY DEVICE

By swivelling the milling fence away, you can achieve an absolutely clear, flat work surface.

OPTION: INTEGRAL FENCE PLATES

Made of tiltable guide bars integrated into the fence plates for a gapless guide surface for all milling operations; precise adjustment to tool diameter and height is achieved by means of infinitely variable adjustment, instead of the standard cast iron fence plates.

DIGITALISATION

Remote maintenance, digital data exchange, machine access control, network-compatible machine, plug and play and HOKUBEMA Cloud.

TECHNICAL SPECIFICATIONS

EQUIPMENT DETAILS

Equipment

CONVENIENT OPERATION

The control panel can be adapted individually to the working method. By simply attaching it to the frame support, the control panel can be used either at the top or bottom.

OPTIONS

Option

DIGITISATION: MACHINE RELEASE

The electronic key system is a simple and cost-effective solution for reliable and secure machine access control, which was previously realised with a key switch or password.

Option

DIGITALISATION: Plug and play

Thanks to the sophisticated system, the old control unit can be disconnected in the event of a fault and replaced with a new control unit sent by HOKUBEMA. A simple plug-in system and the bundled technology in one control module enable quick and efficient problem solving.

Option

DIGITALISATION: Remote maintenance

In the event of a machine malfunction, the system can be accessed remotely and dealt with by the service module. The service technician can then rectify the problem in real time.

Option

DIGITALISATION: HOKUBEMA Cloud

The user interface offers a cloud-based connection for networked working. This gives companies greater independence and a powerful software solution with stability, performance and a high level of security. Digital data exchange makes it easy to download and install updates.

Option

Integral fence plates infeed/outfeed side 500/500 mm

With tiltable guide rods integrated into the fence plates for a gapless guide surface for all milling work; precise adaptation to tool diameter and height is achieved by means of infinitely variable adjustment, instead of standard cast fence plates.

Option

SAFETY GUIDE BAR SET FOR MILLING FENCES

As a continuous guide between the two fence plates, consisting of: 2 safety guide bars 260 x 6 mm, 3 safety guide bars 260 x 3 mm, 1 grooved board made of multiplex 260 x 150 x 12 mm, incl. sliding blocks and Allen key.

Option

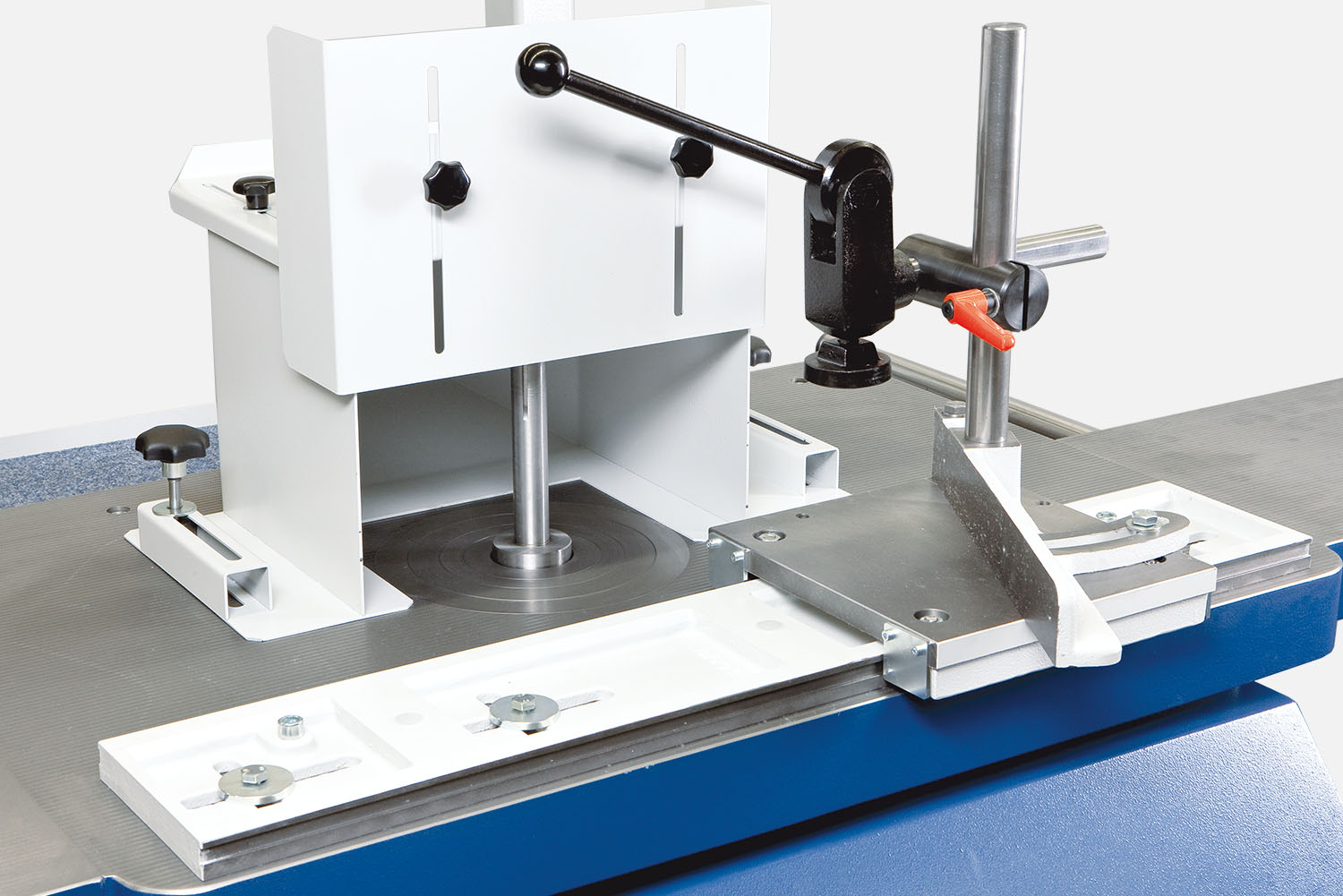

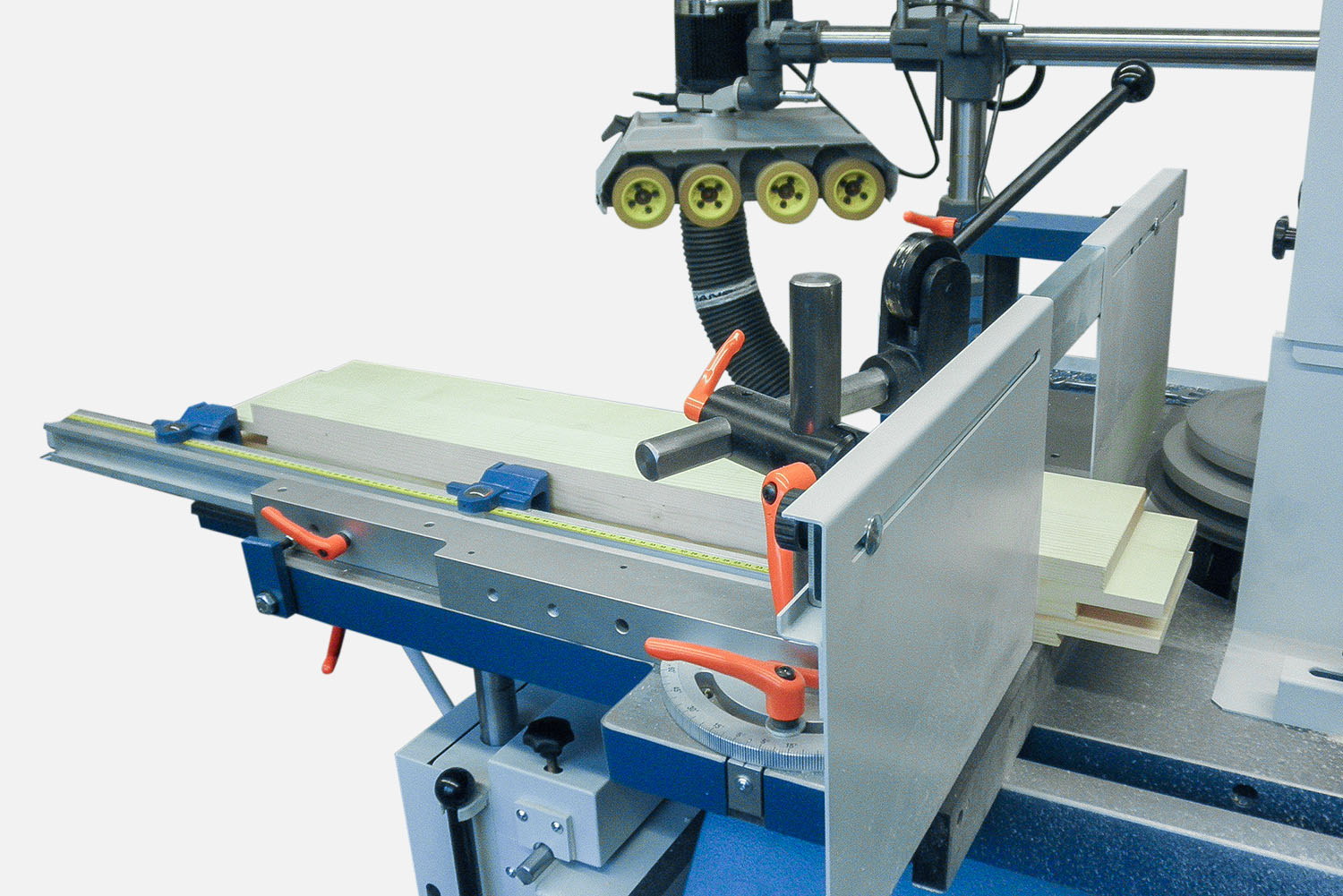

TENONING AND SLOTTING DEVICE 1376

Mounted on the machine table for light tenoning and slotting work with eccentric clamp and mitre-adjustable stop. Sliding stroke 710 mm, height above table approx. 56 mm. The safety guard type 1641 must be used when working with the 1376 tenoning and slotting device.

Option

COMFORT SWIVEL-AWAY DEVICE FOR MILLING FENCES

Electromotive raising and lowering, the fence can be rotated 360° around the guide column and also swivelled forwards.

Option

POWER FEEDER PV 84

4 rollers 120 x 60 mm, 8 speeds: 2/4/5.6/6.7/11/13/16.5/33 m/min, clockwise and anti-clockwise rotation, stand with extension arm 1050 mm, can be used individually horizontally and vertically, incl. mounting, cable and plug.

Option

TABLE TOP EXTENSION ON BOTH SIDES

For table top 1100 x 760 mm, total length 2300 mm, consisting of 2 pieces of finely planed cast table tops as an extension on the left and right of the standard machine table, with smooth-running frame support approx. 892 mm extendable to the front and with emergency stop button.

Option

TABLE TOP EXTENSION ONE-SIDED RIGHT

For table top 1340 x 800 mm, consisting of 1 piece of finely planed cast table top as an extension on the right of the standard machine table, therefore total length 1950 mm including smooth-running frame support approx. 970 mm, extendable forwards and with emergency stop button.

Option

KICK-BACK GUARD 1648

For accident-safe insert milling of long and short parts, infinitely adjustable from 0 - 1500 mm for spindle moulders with table top extension.

Option

SLIDE TABLE

With stop fixture and eccentric clamp, clamping table can be pushed in up to the milling spindle, including guard 1641 and suction nozzle Ø 120 mm, with stepped height adjustment, upper position as slide table, lower position as table extension on the left.

Option

SLIDE PLATE FOR TABLE TOP 1100 X 760 MM

The patented slide plate with grid structure does not change the overall depth when the table slide is set to the maximum table openings. For easy operation, the distance between the front edge and the spindle remains the same. The table slide is infinitely adjustable in depth. A high fitting accuracy without interfering edges is guaranteed.

Option

AUTOMATIC HSK-63-F TOOL CHANGING SYSTEM

Electromechanical clamping system for convenient tool changes. The tool change is actuated via a switch. Includes 1 quick-change arbor HSK-63-F with Ø 30 mm clamping length 140 mm with arbour rings and quick-release nut.