Surface planers and jointers

334 – 335 – 336|20

Motor Power

5,5 kW / 7,5 PH

VOLTAGE

400 V / 50 Hz

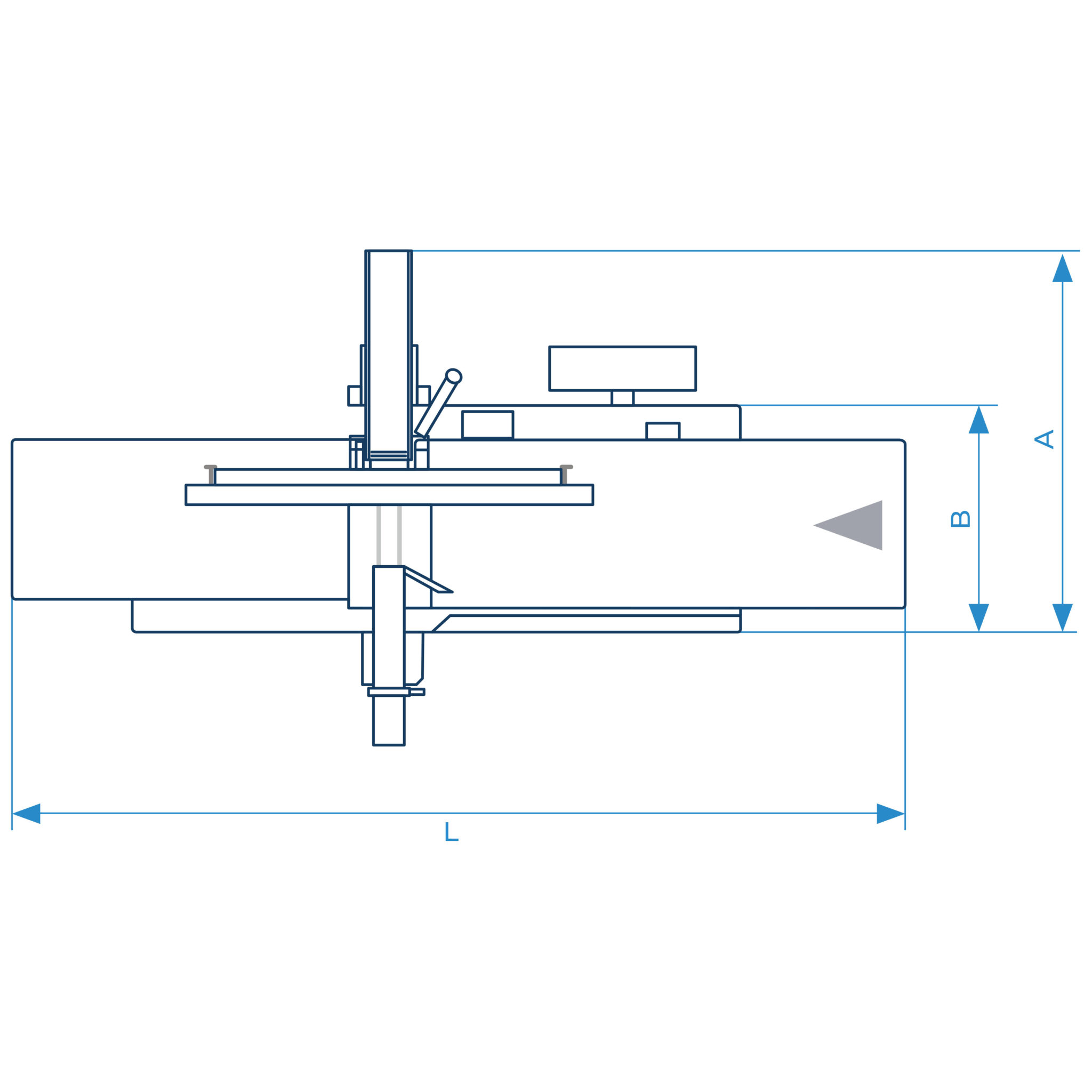

L x D x H in mm

2852 x 1340 x 1587

2852 x 1440 x 1587

2852 x 1560 x 1587

The 334|20 surface planing and jointing machines with 410 mm planing width, 335|20 with 510 mm planing width and 336|20 with 630 mm planing width are characterised by their extremely quiet running in addition to their compact and robust steel construction and the dynamically balanced TERSA cutter block.

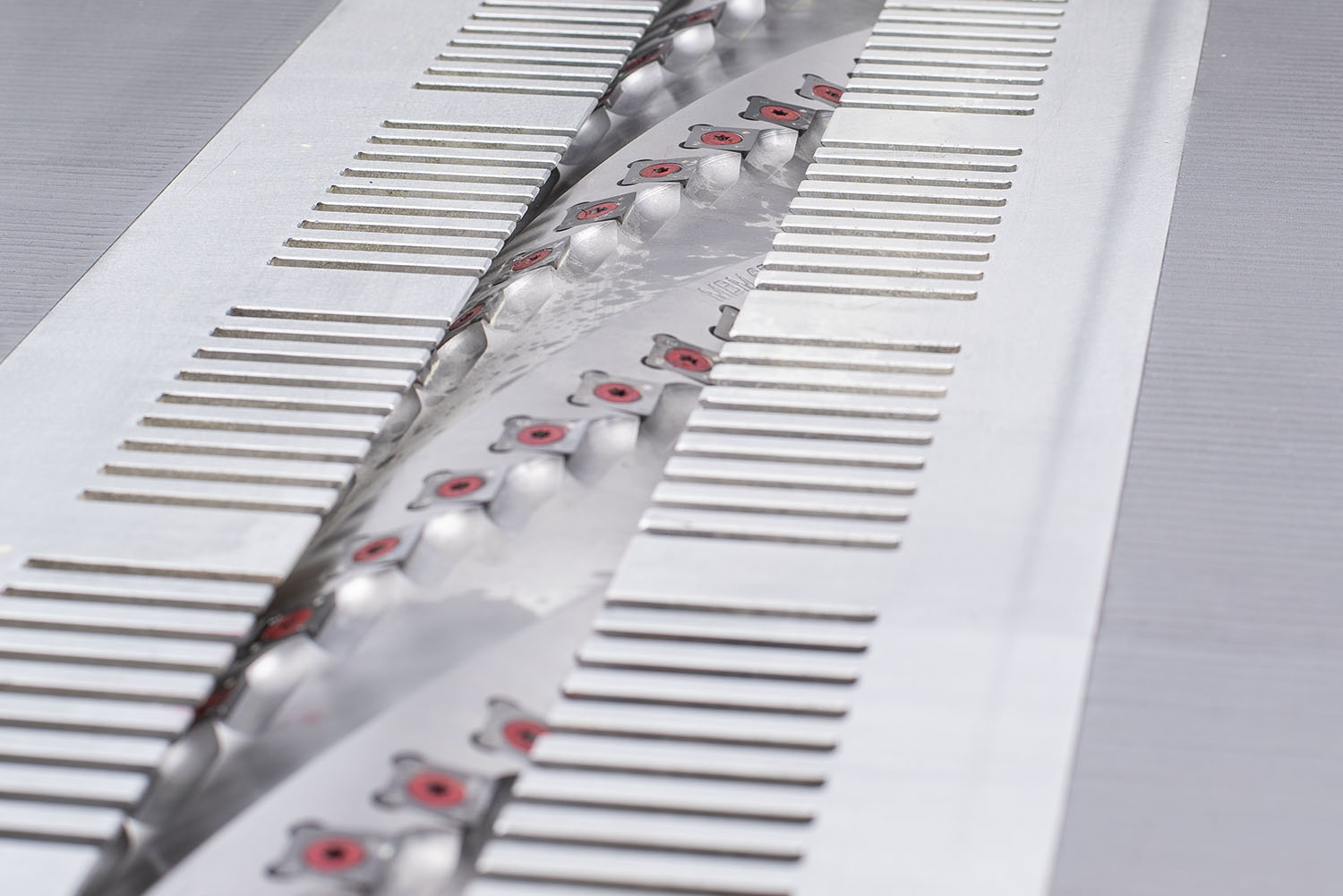

A spiral cutter block is also available as an option. This consists of six knife rows segmented with special 4-fold HM indexable inserts.

The maintenance-free design of the bearing with high-performance precision ball bearings guarantees lasting reliability, maximum precision and a long service life.

The finely planed cast iron tables with a total length of 2,850 mm are mounted vibration-free and ensure a perfect planing result.

The controls for the motorised chip thickness adjustment with touchscreen display are clearly and functionally arranged on the operating side. In addition, the outfeed table can be tilted towards the infeed table via a handwheel so that a hollow or pointed joint can be achieved.

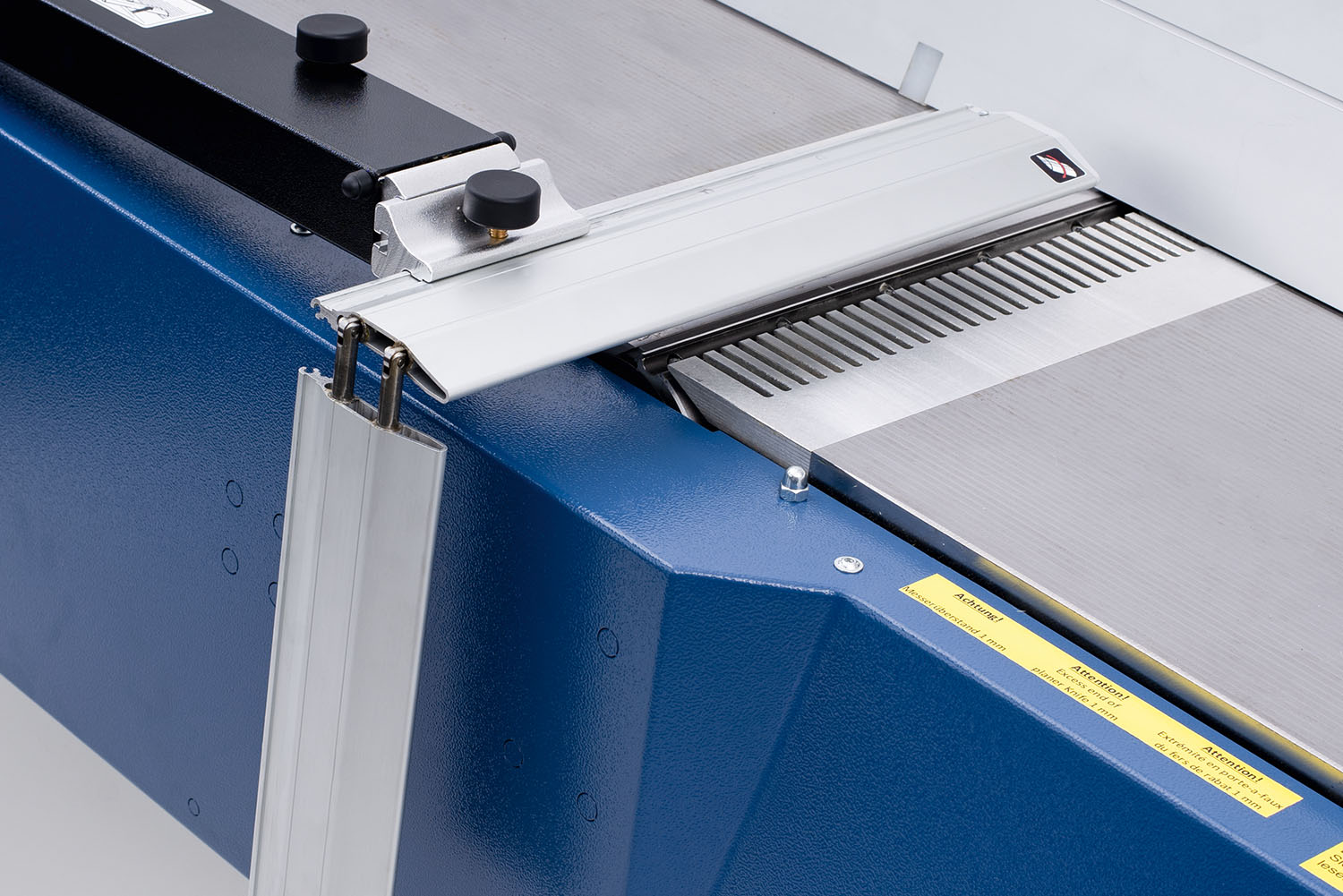

The planer fence with practical one-hand operating lever consists of a thick-walled, anodised two-chamber stop profile. It is easy and intuitive to adjust and can be tilted continuously up to 45°. If necessary, the integrated auxiliary fence can be folded down easily and without tools for immediate use.

Included in the basic equipment is the sturdy standard bridge guard type TXF 1570 for covering the cutter block as well as all necessary safety devices.

ART.-NO.: 4730 (334|20)

ART.-NO.: 4731 (335|20)

ART.-NO.: 4732 (336|20)

SINGLE LEVER DRESSING AND JOINING FENCE

Operated with one hand only, the planing and jointing fence can be set to the desired depth and its angle can be adjusted continuously between 90° and 45°. The additionally integrated auxiliary fence serves as a safe hand rest when machining narrow workpieces.

ERGONOMIC CONTROL PANEL

The control panel with digital display of chip removal and the current status of the infeed table is centrally grouped and positioned at an ideal working height.

TXF 1570 PLANER GUARD

Safety is a high priority here. Areas of the cutter block that are not in use are safely covered by this easily adjustable guard.

WORKING TABLE

The infeed table is adjusted electrically via a pushbutton with an accuracy of 1/10 mm up to 8 mm.

MACHINE DESIGN

The shape of the machine front allows the operator to stand very close to the cutter block and jointing fence. Together with the recess on the underside of the machine, back-friendly working is ensured. Rounded corners on the infeed and dressing table prevent the risk of injury from bumping against it.

OPTION: SPIRAL CUTTER BLOCK

Thanks to the pulling cut, our planers offer you the optimum planing result with the legendary spiral cutter blocks.

SI-TEC PRODUCT

Push block for safe planing of short workpieces. You can purchase these conveniently at any time from our online shop: www.hokubema.com.

TECHNICAL SPECIFICATIONS

EQUIPMENT DETAILS

EQUIPMENT DETAILS

TOUCH DISPLAY FOR CHIP THICKNESS

The chip removal is set in inching mode using push buttons and can be read in milimetres on the new touch display. At the same time, the touch display is used to store machine parameters and to output error and fault messages.

EQUIPMENT DETAILS

SERRATED TABLE LIPS

The serrated table lips are firmly integrated into the worktable. This design ensures noiseless running of the cutter block. To reduce noise, the machine is equipped with serrated table lips as standard.

EQUIPMENT DETAILS

PLANER FENCE

The depth and inclination range of the dressing fence can be adjusted from 90° to 45° using the central one-hand operating lever. If required, the auxiliary stop mounted above the fence can also be folded down.

EQUIPMENT DETAILS

PLANER GUARD TXF 1570

The two-part design allows comfortable working even with large workpieces, as there is no disturbing edge at the front.

OPTIONS

Option

SPIRAL CUTTER BLOCK

The spiral cutter block is equipped with 6 spiral-shaped rows of knives and reversible carbide knives. The pulling cut provides enormous advantages during machining, from enormous noise reduction to long tool life and shorter chips.

Option

PLANER GUARD TX MATIC

The planer guard TX Matic is infinitely adjustable in height and depth. The device is equipped with a two-part cover and thus enables comfortable working on the machine.

Option

PLANER GUARD SUVAMATIC

The Suvamatic planing guard, which can be fixed for series work, is indispensable when planing and jointing workpieces on the planing machine. The safe cutter guard offers many advantages for planing work, including the practical workpiece infeed, the contact pressure as a working aid or the automatic raising and lowering.