Tilting spindle moulder

245|20

Motor Power

5.5 kW / 7.5 HP

VOLTAGE

400 V / 50 Hz

H x W x D in mm

1145 x 1379 x 1484

The solid tilting spindle moulder PANHANS 245|20 enables the economical, flexible and precise machining of wood, wood-like materials and plastic and fits with its compact external dimensions into every joinery or workshop.

The spindle is driven by a powerful 5.5 kW three-phase motor whose four speeds (3000, 4500, 6000 and 9000 rpm) can be selected by shifting the drive belt via a practical quick-release device.

The height and tilt adjustment of the milling spindle is carried out here completely by electric motor, through the prior input of corresponding target values into the touchscreen control built into the control panel. The control can also be used to position offset dimensions, calibrate the height and angle of the milling spindle and indicate the currently set speed.

The milling spindle, mounted in dust-tight special ball bearings, can be adjusted in height by 125 mm and tilted in the range 5° to +45.5° (optionally ±45°).

For an easy and quick tool change, the machine is equipped with a quick clamping device. As an option to the standard milling spindle, the machine can also be supplied with an HKS-80 quick-change system with spindle lock and milling arbor in the desired diameter.

The finely planed table of the tilting spindle moulder measures 1100 x 760 mm and is made of thick-walled, highly ribbed and torsion-resistant grey cast iron. If required, the support surface can be extended by optional table extensions, and instead of the rigid standard frame support, an extendable frame support can be supplied on request.

The standard version has the type 216 safety fence including cast fence plates, aluminium splinter tabs and protective bonnet. The total fence is adjusted via a built-in handwheel with digital LCD position indicator. The partial fence is adjusted via a star knob using a vernier scale.

For safe machining, the machine is also equipped with a protection and pressure device, a ring fence and all necessary safety equipment.

Also included as standard is a machine socket for connecting an optional power feeder. The machine's range of functions can be expanded as needed with a large portfolio of options and special equipment.

ART. NO. 4529

MACHINE CONSTRUCTION

Solid mechanical engineering "Made in Germany" for a long service life and precise operation.

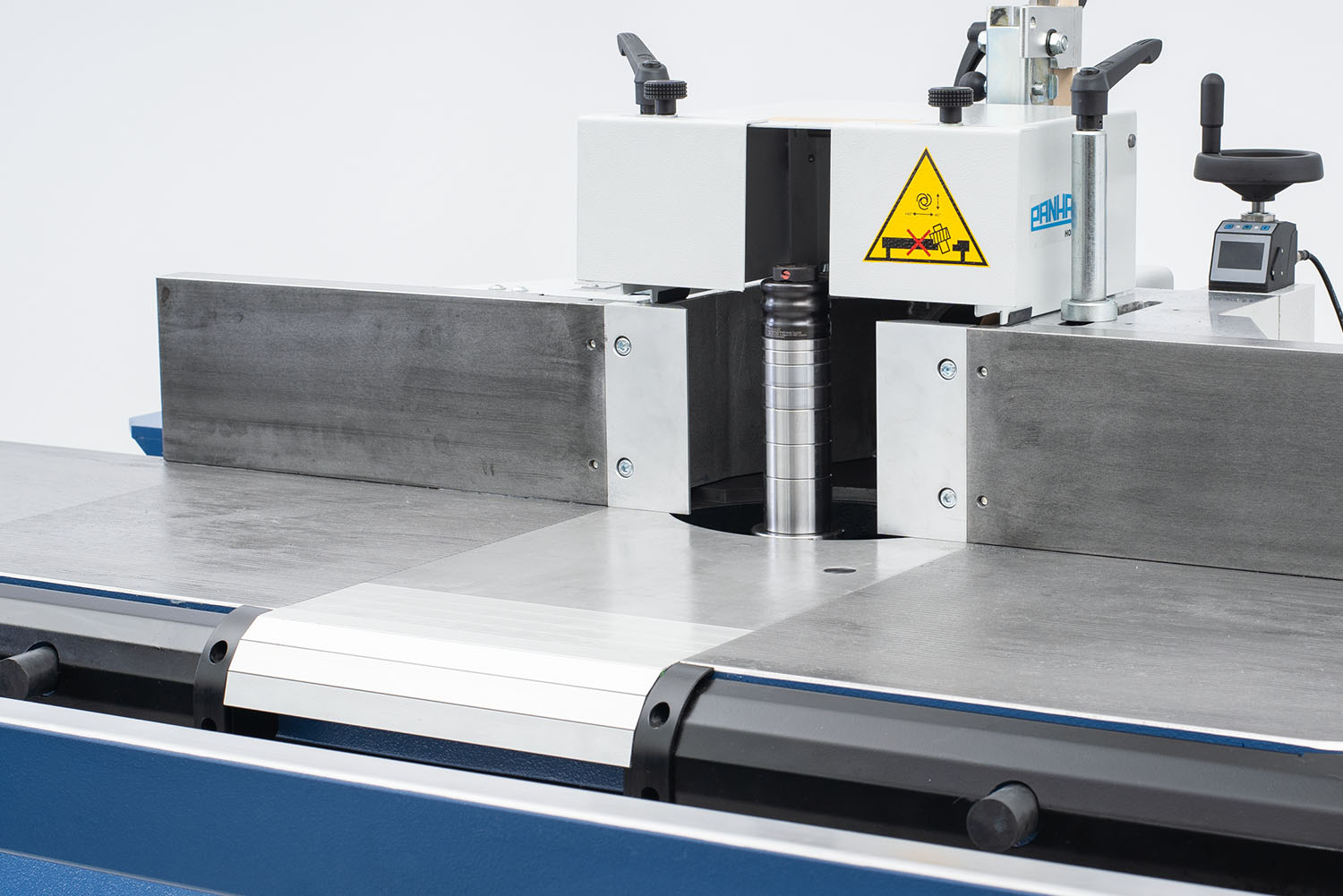

MILLING FENCE

Safety fence 216 with overall adjustment via handwheel and LCD display incl. cast plates and aluminium splinter tabs.

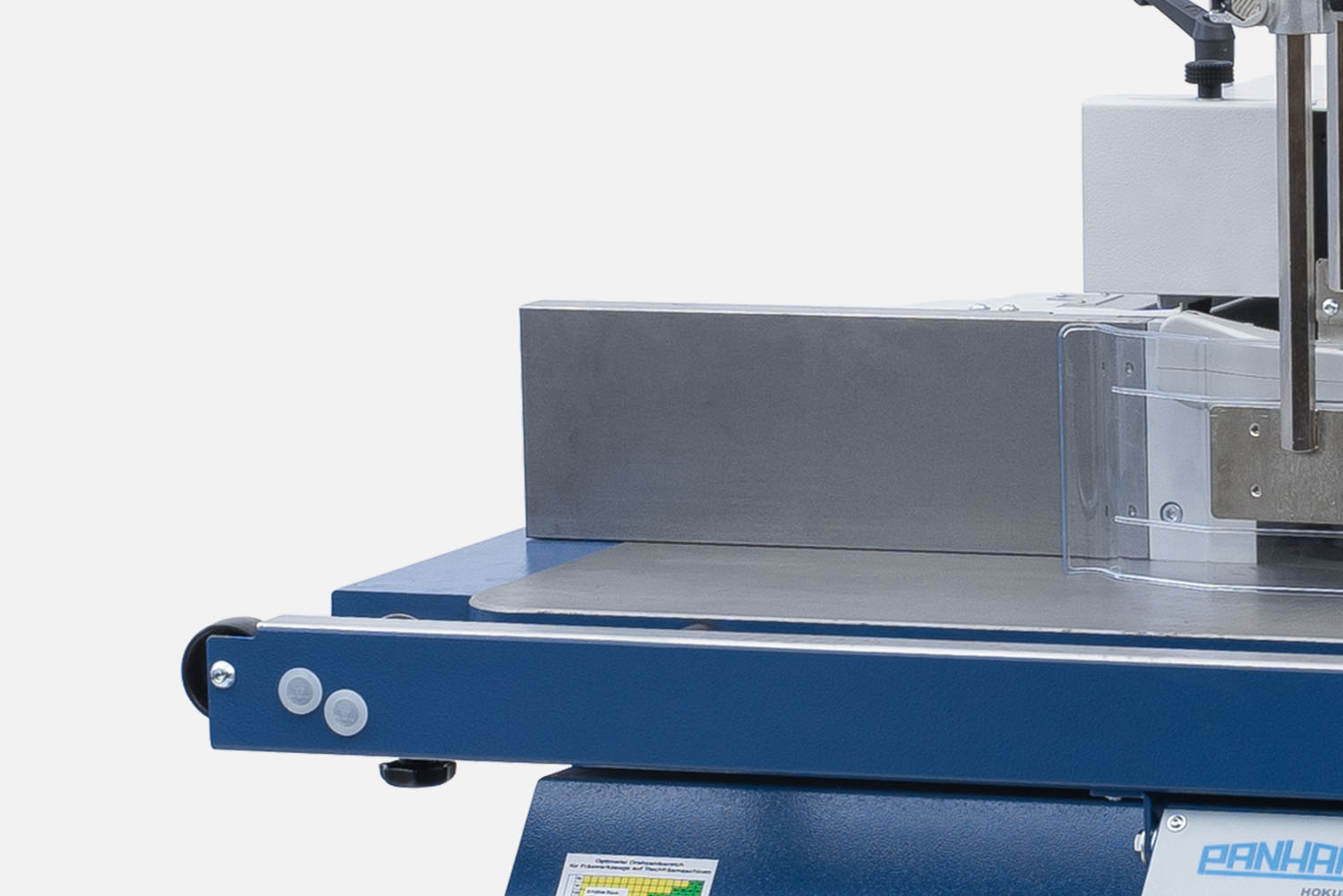

CAST IRON TABLE

The table is made of thick-walled, highly ribbed and torsion-resistant grey cast iron. With rigid frame support as standard.

CONTROL UNIT

Digital position and speed indicator. Motorised height and tilt adjustment of the milling spindle via positioning control as well as pushbuttons for climb milling and conventional milling.

MILLING SPINDLE

Spindle moulder with fixed milling spindle tiltable on one side for a tilt range of -5° to +45.5°. Milling spindle Ø 30 mm.

SAFETY

A wide range of functions ensure greater safety when working, such as a lockable main switch and electric motor brake.

QUICK BELT TENSIONING DEVICE

Four belt-adjustable speeds of 3000 / 4500 / 6000 / 9000 rpm make it possible to work with maximum precision and at the highest quality level.

TECHNICAL SPECIFICATIONS

EQUIPMENT DETAILS

EQUIPMENT DETAILS

POSITIONING VIA TOUCHSCREEN CONTROL

The height and tilt adjustment as well as the zeroing of the height and offset measurement are carried out via a touchscreen positioning control. Exact values can be entered using the input keyboard. Additional pushbuttons for positioning, spindle start and stop as well as a direction of rotation switch are located next to the input buttons on the control panel.

EQUIPMENT DETAILS

MILLING SPINDLE WITH QUICK CLAMPING NUT

The 30 mm milling spindle has a quick-release nut for quick tool changes and process optimisation in your workshop workflow.

EQUIPMENT DETAILS

CONTROL PANEL AT EYE LEVEL

In the current version, the control panel is ergonomically and user-friendly mounted on the right-hand side behind the table top, so that the controls are always at eye level.

OPTIONS

Option

TILT RANGE OF THE MILLING SPINDLE

+/- 45,5°

Instead of +45.5° to -5°, you can optionally extend the tilt range of the milling spindle to +45.5° to -45.5°, which enables a generous range of applications. (photo includes optional table slide)

Option

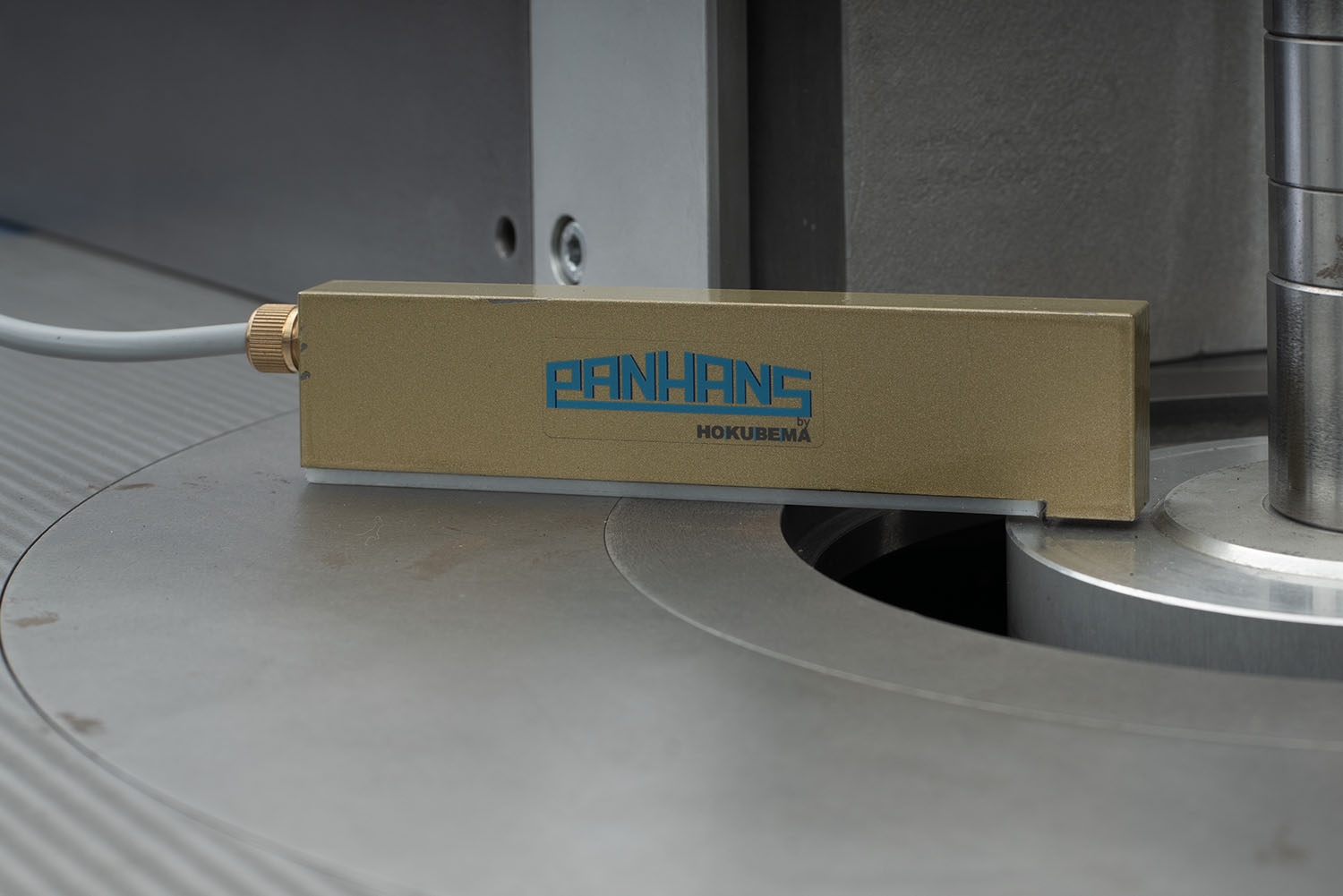

TURNTABLE

The turntable can be used to rotate the milling fence type 216 on the machine table by 360°.

Option

SAFETY GUIDE BAR SET FOR MILLING FENCES

As a continuous guide between the two fence plates, consisting of: 2 safety guide bars 260 x 6 mm, 3 safety guide bars 260 x 3 mm, 1 grooved board made of multiplex 260 x 150 x 12 mm, incl. sliding blocks and Allen key.

Option

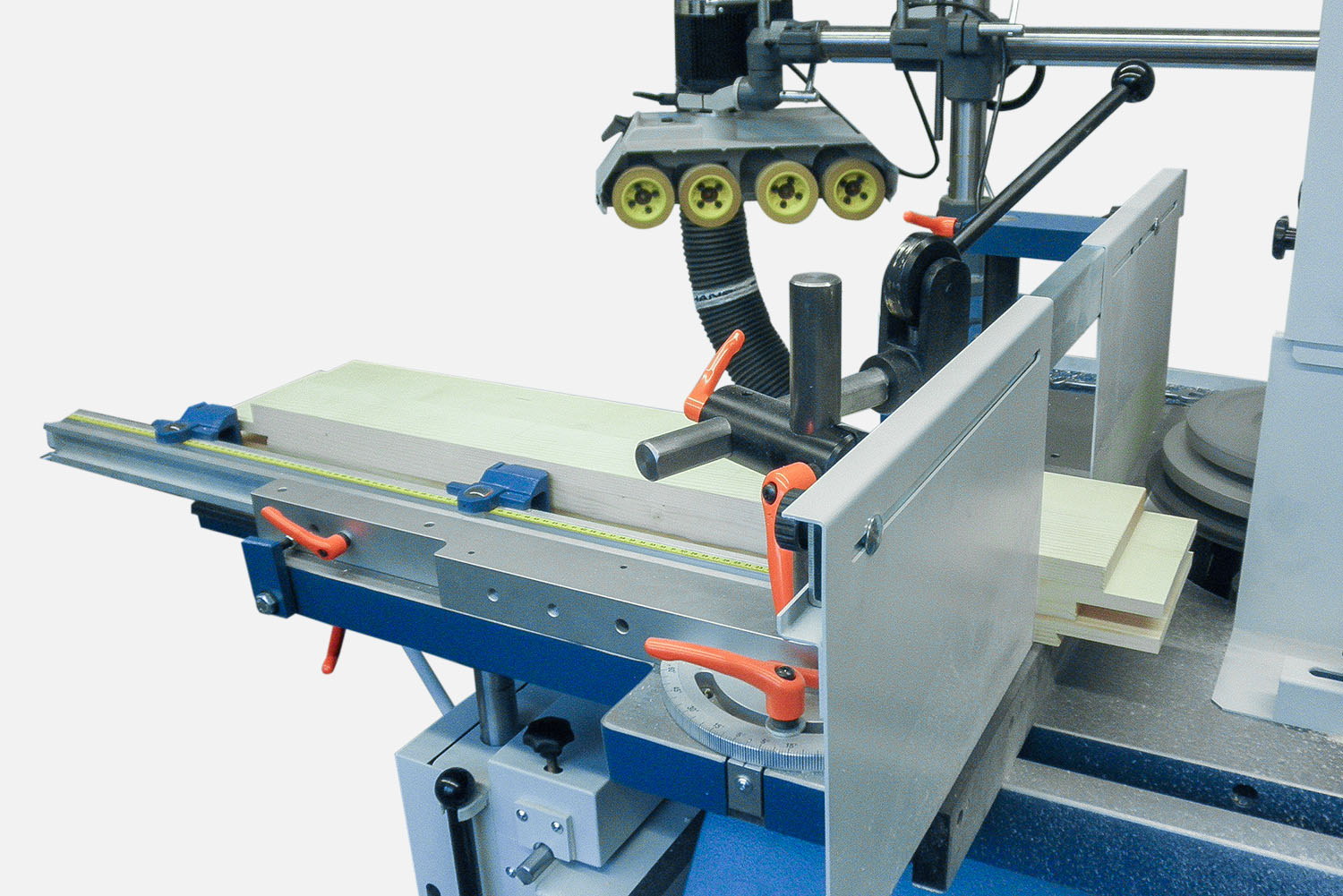

POWER FEEDER PV 84

4 rollers 120 x 60 mm, 8 speeds: 2/4/5.6/6.7/11/13/16.5/33 m/min, clockwise and anti-clockwise rotation, stand with extension arm 1050 mm, can be used individually horizontally and vertically, incl. mounting, cable and plug.

Option

POWER FEEDER VARIOMATIC 4 N

4 rollers, infinitely variable feed rate from 2 - 18 m/min clockwise and anti-clockwise rotation, quick change from horizontal to vertical use. Easy swivelling and positioning with memory lock system. With comfort stand, numerical height display, extension arm 1050 mm long, incl. mounting, cable and plug.

Option

KICK-BACK GUARD 1648

For accident-safe insert milling of long and short parts, infinitely adjustable from 0 - 1500 mm for spindle moulders with table top extension.

Option

ZEROMASTER CALIBRATOR

For exact 0-point height adjustment and referencing of the cutter head in relation to the table top.

Option

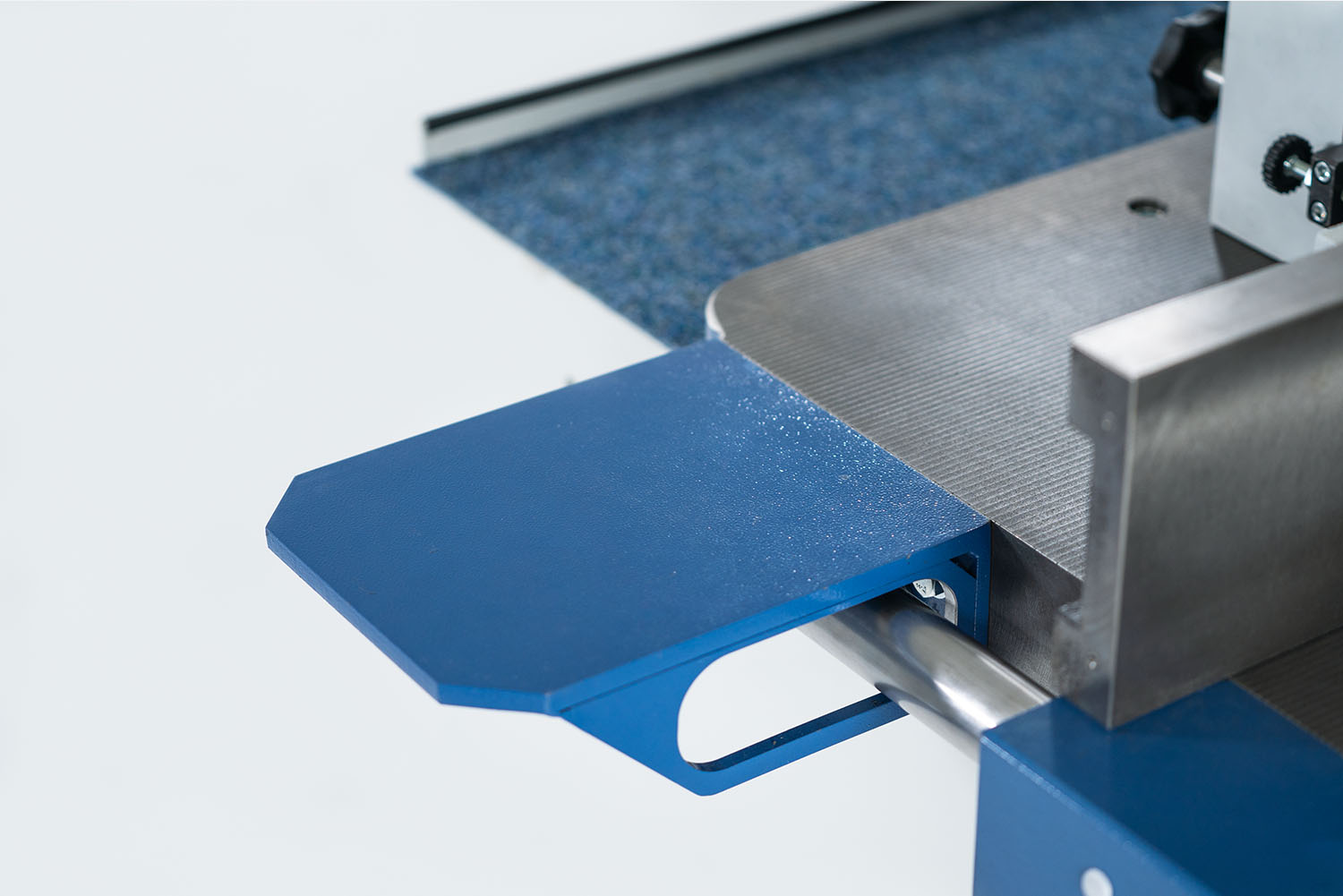

SLIDE PLATE FOR TABLE TOP 1100 X 760 MM

The patented slide plate with grid structure does not change the overall depth when the table slide is set to the maximum table openings. For easy operation, the distance between the front edge and the spindle remains the same. The table slide is infinitely adjustable in depth. A high fitting accuracy without interfering edges is guaranteed.

Option

EXTENDABLE FRAME SUPPORT, FOR TABLE TOP 1100 X 760 MM

Total length approx. 1375 mm, extension depth approx. 892 mm from the centre of the milling spindle, guided in separate bearing blocks on the side of the machine table, smooth-running and with emergency stop button.

Option

TABLE TOP EXTENSION ON BOTH SIDES

For table top 1100 x 760 mm, total length 2300 mm, consisting of 2 pieces of finely planed cast table tops as an extension on the left and right of the standard machine table, with smooth-running frame support approx. 892 mm extendable to the front and with emergency stop button.

Option

TABLE TOP EXTENSION ONE-SIDED RIGHT

For table top 1340 x 800 mm, consisting of 1 piece of finely planed cast table top as an extension on the right of the standard machine table, therefore total length 1950 mm including smooth-running frame support approx. 970 mm, extendable forwards and with emergency stop button.

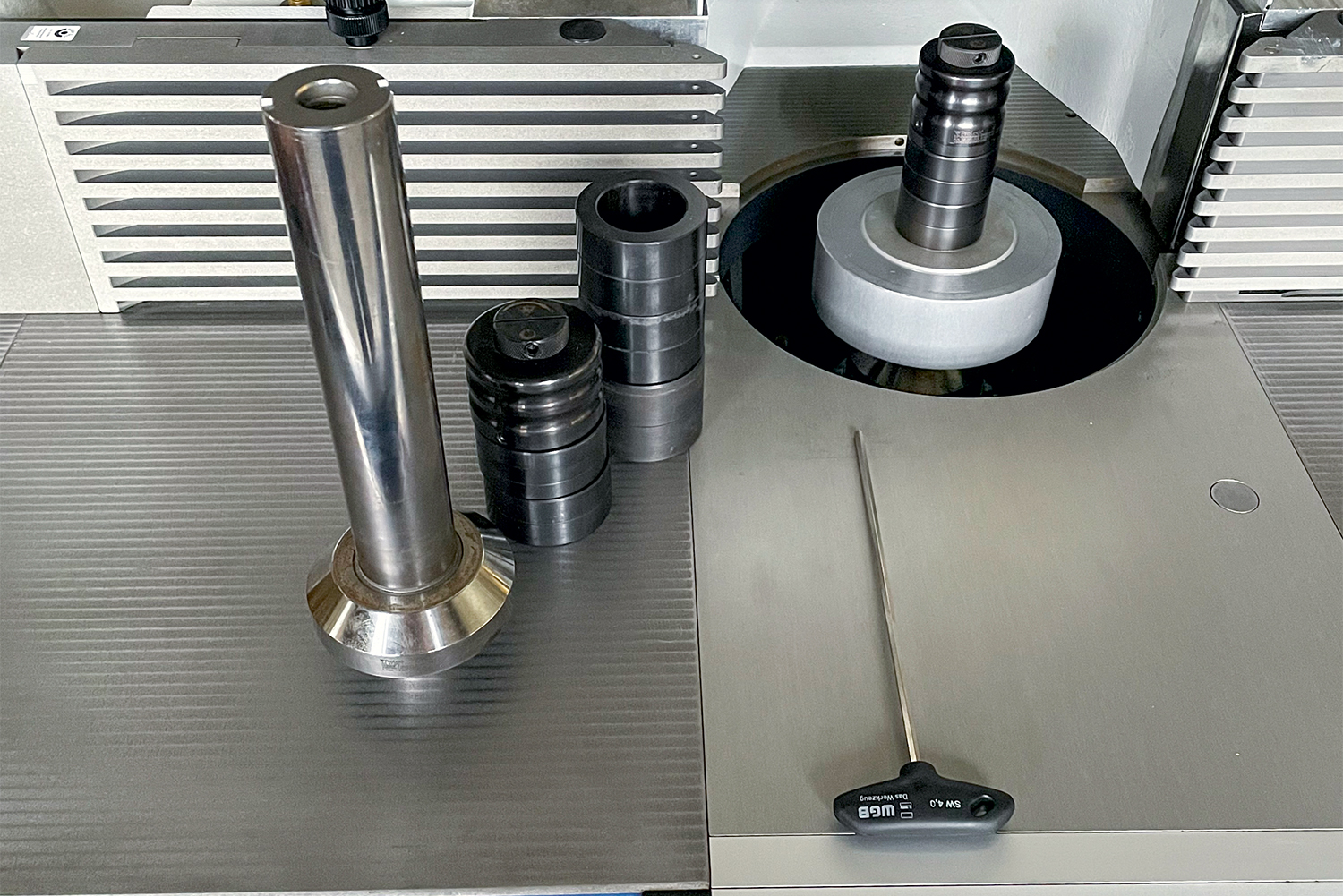

Option

Manual HSK 80 quick tool changing system

Instead of fixed standard milling spindle, optional HSK system as interface for various Sclamping spigot diameters; with 30 mm milling arbor and quick-release nut. Unique system, as it ensures greater concentricity and enables easy replacement of the milling arbours. Other mandrels with different Ø available on request. Optionally with spanner nut instead of quick-release nut.

Option

Milling arbour HSK 80 Ø 40 mm

Replaceable, dynamically balanced for optimum concentricity, clamping height 160 mm with milling arbor rings and cutter quick-clamping device via Allen key with spindle lock, instead of standard milling spindle 30 mm, available in various diameters, for example 40 mm (note: other milling arbor diameters on request).

Option

Integral fence plates infeed/outfeed side 500/500 mm

With tiltable guide rods integrated into the fence plates for a gapless guide surface for all milling work; precise adaptation to tool diameter and height is achieved by means of infinitely variable adjustment, instead of standard cast fence plates.

Option

Swivelling console

Mounted on the left of the machine stand with joint for swivelling away the power feeder, mandatory for slide table no. 4491.1 as well as milling fences 204, 302, 320 and integral fence plates 650 + 650 mm.

Option

RIGID CONSOLE

For mounting a power feeder approx. 195 x 180 mm on the left side of the table top; mandatory when using milling fences 204, 302, 320 and integral fence plates 650 + 650 mm, with table top 1100 x 760 mm.

Option

MILLING FENCE 204

Made of die-cast aluminium, with aluminium splinter tabs, for holding optional safety rulers and grooved board. Total adjustment via handwheel and LCD display to 0.1 mm, adjustment range approx. 140 mm, fence plate adjustment on the right via handwheel and LCD display to 0.1 mm, adjustment range approx. +10 to -22 mm with comfort clamping on the machine table.

Option

CENTREX

Protective and pressure device for securely holding workpieces in place during manual milling work; the special shape of the pressure shoe ensures precise workpiece guidance during all milling work, attached to the milling fence, can be folded up, instead of the standard GAMMA V 1629 protective and pressure device.

Option

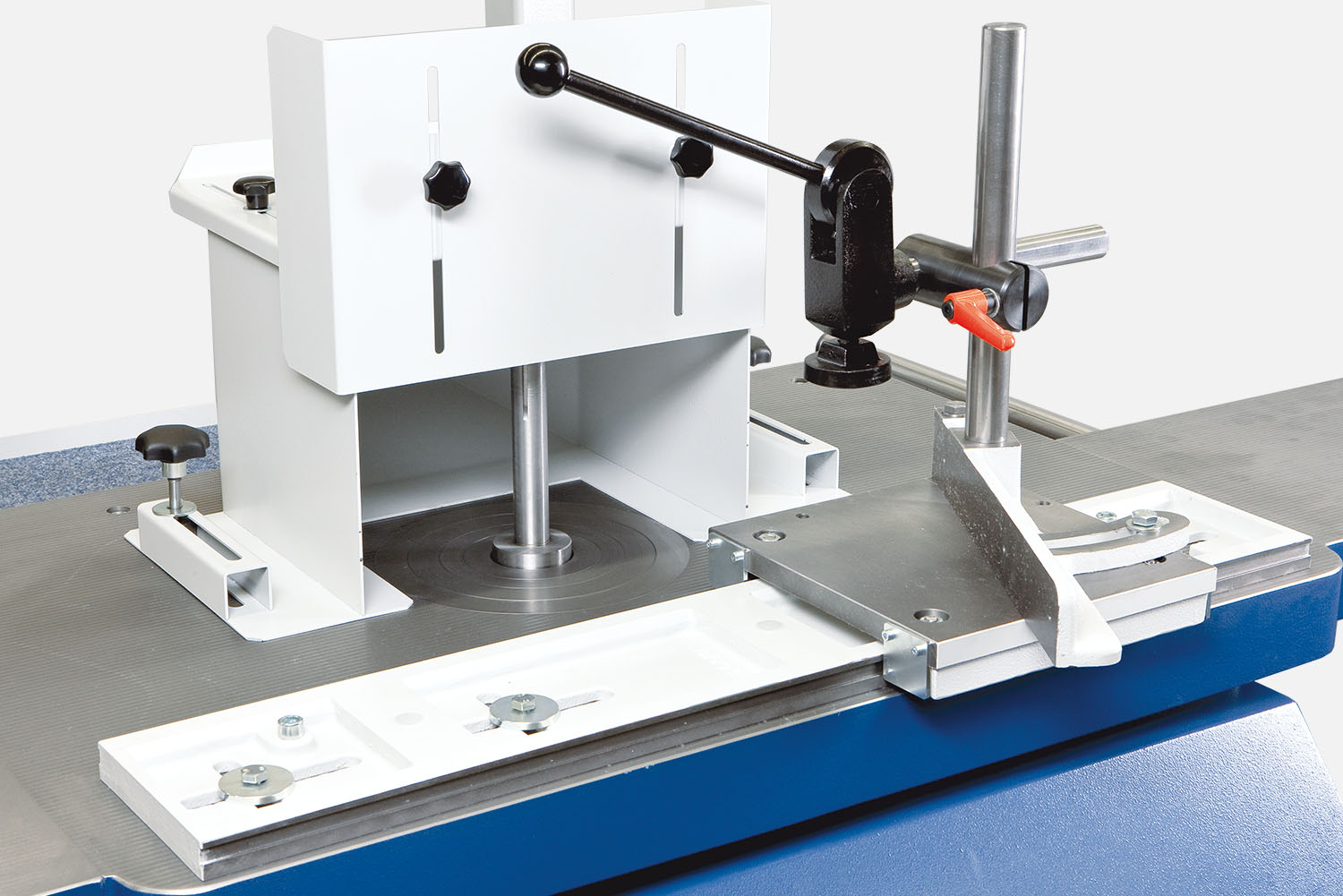

TENONING AND SLOTTING DEVICE 1376

Mounted on the machine table for light tenoning and slotting work with eccentric clamp and mitre-adjustable stop. Sliding stroke 710 mm, height above table approx. 56 mm. The safety guard type 1641 must be used when working with the 1376 tenoning and slotting device.

Option

SAFETY GUARD 1641

For the tenoning and slotting device, with suction nozzle Ø 120 mm for tool diameters from 250 to 350 mm.

Option

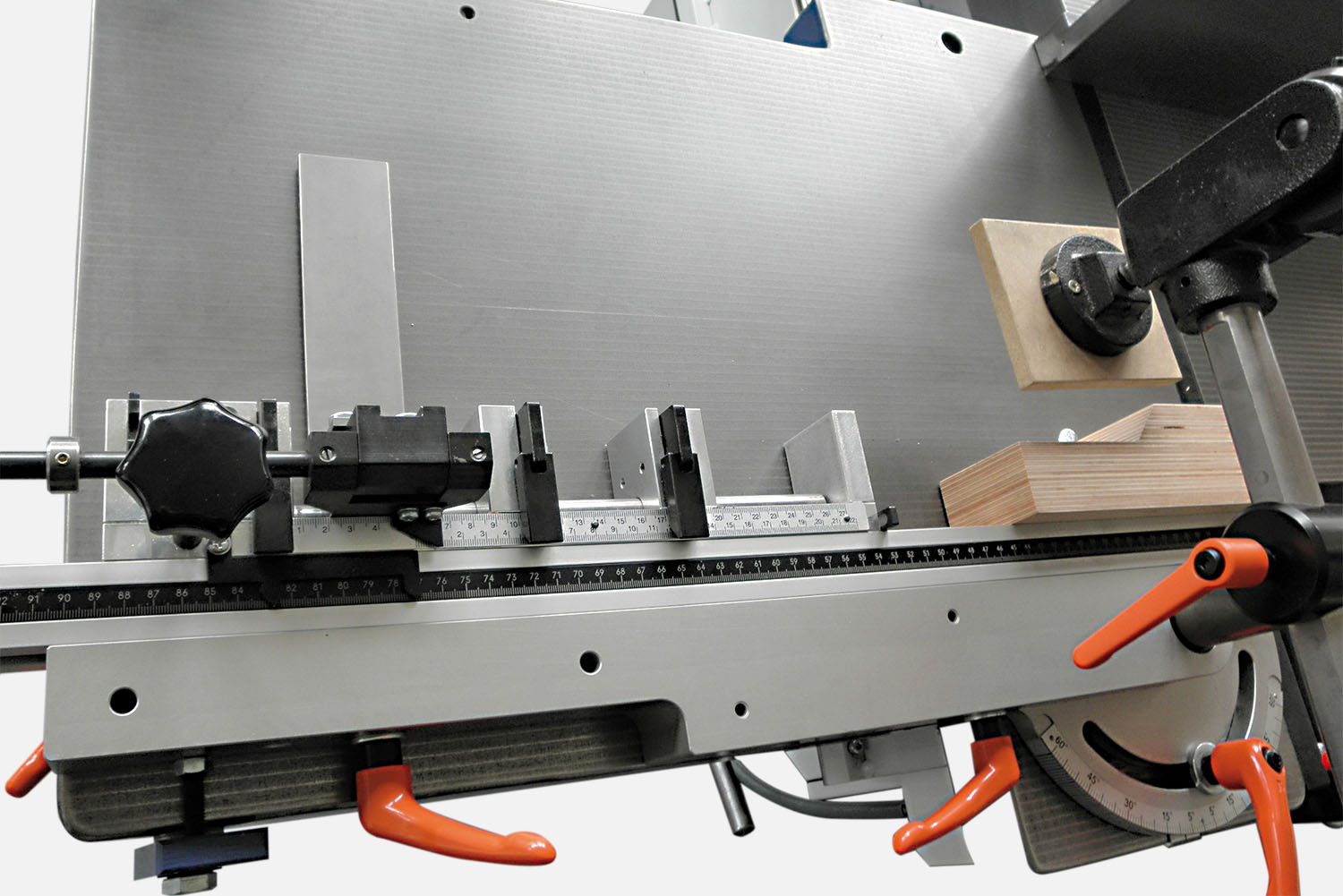

CROSS-CUT FENCE LAS-M AND EXTENSION

With its length of 1750 mm, the LAS-M cross-cut fence is the ideal complement to the slide table with article number 4491.1. As a further option, the extension to the LAS-M cross-cut fence can be extended up to 2750 mm.

Option

SLIDE TABLE

With stop fixture and eccentric clamp, clamping table can be pushed in up to the milling spindle, incl. safety guard 1641, suction nozzle Ø 120 mm, with stepped height adjustment, upper position as slide table, lower position as table extension on the left.